Truck air bag systems are an essential safety feature that every truck owner should be familiar with. In this blog post, we will explore the importance of truck air bag systems, their components, and how they work to protect you on the road. We will also discuss the advantages of having a truck air bag system, the different types available, as well as common issues that may arise and how to troubleshoot them. Additionally, we will provide maintenance tips to ensure your truck air bag system is in optimal condition, and finally, we will touch on the topic of upgrading your existing system for enhanced safety.

What is a truck air bag system?

What is a Truck Air Bag System?

A truck air bag system is a safety feature installed in trucks to provide additional protection to drivers and passengers during accidents or collisions. Similar to the airbags found in passenger cars, these specialized air bag systems are designed specifically for heavy-duty trucks and offer enhanced safety measures in case of a crash. The purpose of a truck air bag system is to minimize the impact force experienced by occupants and reduce the risk of severe injuries or fatalities.

Truck air bag systems consist of various components that work together to ensure effective deployment and inflation of the airbags. The main components of a typical truck air bag system include the airbag itself, an electronic control unit (ECU), crash sensors, and a diagnostic module. The airbag is typically made of a sturdy fabric material and filled with compressed gas, such as nitrogen or argon. It is strategically positioned within the truck’s cabin to provide cushioning and protection.

When a collision occurs, the crash sensors in the truck detect the impact and send a signal to the ECU. The ECU then triggers the airbag deployment system, which releases the compressed gas and inflates the airbag in a fraction of a second. The rapid inflation of the airbag creates a cushioning effect that absorbs the energy generated by the impact and reduces the chance of occupants hitting the truck’s interior components or being ejected from the vehicle.

The advantages of a truck air bag system are numerous. Firstly, it can significantly reduce the risk of severe injuries or fatalities in truck accidents. By absorbing the impact force and restraining occupants, airbags can prevent direct contact with hard surfaces or objects within the cabin. Secondly, truck air bag systems are compatible with other safety features like seat belts, providing an added layer of protection when used in combination. Additionally, the deployment and inflation of airbags happen within milliseconds, ensuring quick and effective response in critical situations.

- Enhances occupant safety during truck accidents

- Reduces the risk of severe injuries or fatalities

- Compatible with seat belts and other safety features

- Rapid deployment and inflation for quick response

While truck air bag systems offer crucial safety benefits, they are not without their issues. Common problems that can arise with these systems include faulty sensors, wiring issues, or malfunctions in the ECU. Additionally, airbags may not deploy properly if they have been previously deployed and not replaced or if maintenance and inspections are neglected. Regular maintenance and troubleshooting can help prevent these issues and ensure the proper functioning of a truck air bag system.

In summary, a truck air bag system is a safety feature designed to protect occupants in case of truck accidents. It works by deploying and inflating airbags to absorb the impact force and minimize injury risks. These systems consist of various components, such as the airbag, ECU, crash sensors, and diagnostic module. While providing numerous advantages, it is important to ensure regular maintenance and address any potential issues to maximize the effectiveness of a truck air bag system.

Importance of a truck air bag system

The Importance of a Truck Air Bag System

When it comes to the safety of both drivers and passengers, a truck air bag system plays a crucial role. This essential safety mechanism has proven to be a lifesaver in countless accidents and has significantly reduced the severity of injuries. The purpose of a truck air bag system is to provide a cushioning effect during a collision, minimizing the impact on occupants and preventing them from forcefully hitting the vehicle’s interior components.

One of the primary reasons why a truck air bag system is important is its ability to protect passengers from severe injuries. In the event of a collision, the airbags rapidly inflate to provide a soft and protective barrier, reducing the risk of head, chest, and neck injuries. The force exerted on the body when colliding with the interior surfaces of a truck during an accident can be extremely harmful, but airbags help distribute and absorb this force, minimizing the potential for serious harm.

Another significant aspect of a truck air bag system is that it enhances the effectiveness of seat belts. Seat belts are crucial for preventing occupants from being thrown out of the vehicle during a collision. However, seat belts alone may not be able to effectively protect against severe internal injuries caused by the impact. The combination of seat belts and airbags forms a powerful safety duo, greatly reducing the risk of life-threatening injuries and increasing the likelihood of survival in a crash.

List of advantages offered by a truck air bag system:

- 1. Enhanced Safety: Airbags provide an additional layer of protection, minimizing injuries and increasing the overall safety of the truck.

- 2. Injury Reduction: The cushioning effect of airbags helps prevent severe head, chest, and neck injuries.

- 3. Effective Supplementary System: Airbags work in conjunction with seat belts to provide comprehensive protection for occupants.

- 4. Increased Survival Rate: The combination of seat belts and airbags significantly improves the chances of surviving a collision.

A truck air bag system comprises various components, including sensors, inflators, and the airbag module itself, all working together to detect a collision and deploy the airbags promptly. These components ensure reliable and fast deployment of the airbags to protect occupants during accidents. Additionally, regular maintenance and troubleshooting of the air bag system are vital to ensuring it functions properly when needed.

Overall, the importance of a truck air bag system cannot be overstated. It plays a critical role in safeguarding occupants and mitigating the severity of injuries during accidents. By investing in a reliable and properly functioning air bag system, truck owners can prioritize the safety and well-being of everyone on board, thereby preventing avoidable tragedies. It is essential to understand the significance of this safety feature and make it a priority when considering truck safety measures.

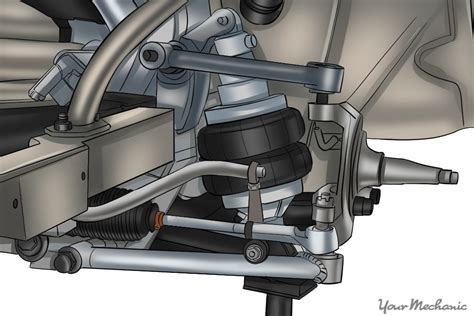

Components of a truck air bag system

The truck air bag system is an integral part of a vehicle’s safety features. It is designed to provide cushion and protection in the event of a collision or sudden impact. Understanding the components of a truck air bag system is essential in comprehending how it functions and contributes to passenger safety.

There are several key components that make up a truck air bag system:

- Airbags: These are the primary safety devices within the system. They are made of durable fabric and are inflated rapidly when a collision occurs. Airbags are typically located in the steering wheel, dashboard, and side panels of the vehicle, providing protection to occupants in different impact scenarios.

- Sensors: Sensors play a critical role in the functioning of the air bag system. They are strategically placed throughout the vehicle to detect any sudden deceleration or impact. When triggered by a collision, the sensors send a signal to the airbag control module, which then initiates the deployment of airbags.

- Airbag Control Module: The airbag control module is the brain of the air bag system. It receives data from the sensors and determines whether to deploy the airbags. The module is programmed with sophisticated algorithms to accurately assess the severity of a collision, ensuring timely and appropriate airbag deployment.

Additionally, there are supplementary components that support the proper functioning of the truck air bag system:

| Component | Description |

|---|---|

| Crash Sensors | These sensors are specifically designed to detect frontal collisions. They provide essential data to the airbag control module, which then deploys the necessary airbags. |

| Seat Belt Pretensioners | Seat belt pretensioners are responsible for reeling in the seat belts tightly upon impact. This action helps to minimize the movement of occupants and further enhances their safety. |

| Impact Sensors | These sensors detect side collisions and trigger the appropriate side airbags to deploy. They are typically located in the doors or side panels of the vehicle. |

| Airbag Warning Light | The airbag warning light is an indicator on the dashboard that alerts the driver to any issues with the airbag system. If this light illuminates, it is essential to have the system checked by a professional. |

In conclusion, the components of a truck air bag system work together to provide invaluable safety measures in the event of a collision. The airbags, sensors, airbag control module, and supplementary components ensure quick and effective deployment of airbags to protect occupants from potential injuries. Regular maintenance and prompt attention to any warning signs are crucial to keeping the truck air bag system in optimal condition.

How does a truck air bag system work?

A truck air bag system is an essential safety feature that is installed in commercial trucks to provide protection in the event of a collision. It works by utilizing sensors and airbags to cushion the impact and reduce the severity of injuries to occupants inside the vehicle. Understanding how a truck air bag system works can help drivers and passengers feel more secure on the road.

The main components of a truck air bag system include the sensors, control module, airbags, and the inflation system. When a collision occurs, the sensors detect the sudden deceleration and send signals to the control module. The control module then activates the inflation system, which triggers the release of compressed gas into the airbags, causing them to rapidly inflate.

The inflation of the airbags happens within milliseconds, creating a protective cushion between the occupants and the hard surfaces inside the vehicle. This helps to prevent injuries by absorbing the impact and reducing the forces exerted on the body. The airbags deflate immediately after inflation, allowing the occupants to move freely and safely within the vehicle.

To ensure that the truck air bag system works effectively, it is important to regularly maintain and inspect the components. This includes checking the sensors and control module for any signs of damage or malfunction, as well as ensuring that the airbags are properly installed and not expired. It is also crucial to follow the manufacturer’s instructions for maintenance and inspection intervals.

While a truck air bag system provides significant safety benefits, it is important to note that it is not a substitute for seat belts. Seat belts should always be worn in conjunction with the airbags to maximize protection. Additionally, it is essential to drive safely and responsibly to avoid accidents and minimize the need for the air bag system to deploy.

Advantages of a truck air bag system

Truck air bag systems have become an essential safety feature in modern vehicles. These systems offer significant advantages that can potentially save lives and protect truck drivers in the event of a collision. In this blog post, we will explore the various advantages of a truck air bag system and how it enhances the overall safety of truck drivers and their vehicles.

1. Enhanced Protection: One of the primary advantages of a truck air bag system is the enhanced protection it provides in the event of a collision. When the system detects a sudden impact, it quickly inflates the airbags to cushion the occupants and minimize the risk of severe injuries. The airbags act as a barrier between the driver/passengers and the hard surfaces inside the truck, reducing the impact forces and preventing them from hitting objects directly.

2. Reduced Injury Severity: The deployment of truck air bags in a collision significantly reduces the severity of injuries sustained by the occupants. The sudden release of air from the inflated airbags absorbs a large portion of the impact energy, thereby minimizing the chances of head and chest injuries. The system is designed to work in conjunction with seat belts, ensuring that the occupants are held securely in place during a collision and reducing the risk of secondary impacts.

3. Prevention of Ejection: Another advantage of a truck air bag system is its ability to prevent ejection from the vehicle. In severe accidents, the force generated can be strong enough to eject individuals through windows or doors. However, the deployment of airbags can help keep the occupants within the confines of the truck, preventing them from being thrown out and reducing the risk of severe injuries or fatalities.

4. Enhanced Vehicle Stability: Truck air bag systems also contribute to enhancing vehicle stability during certain driving conditions. For instance, when a truck encounters a strong gust of wind or navigates a sharp curve, the sensors in the air bag system can detect the lateral movements and adjust the air pressure in the bags accordingly. This adjustment helps in stabilizing the truck and maintaining control, reducing the risk of rollovers or loss of control accidents.

5. Saving on Insurance Costs: Having a truck equipped with an air bag system can also lead to savings on insurance costs. Insurance companies often provide discounts or lower premiums to truck owners who have installed safety features like air bags. These discounts not only reward responsible driving but also help to offset the initial investment in installing a truck air bag system.

Overall, the advantages of a truck air bag system cannot be understated. From enhanced protection and reduced injury severity to prevention of ejection and improved vehicle stability, these systems play a crucial role in ensuring the safety of truck drivers. Additionally, the potential cost savings in insurance premiums make it a valuable investment for both truck owners and operators.

Different types of truck air bag systems

In the world of truck safety, air bags play a crucial role in protecting drivers and passengers from severe injuries during accidents. While we are all familiar with air bags in cars, truck air bag systems are specially designed to meet the needs of larger vehicles. Today, we will delve into the various types of truck air bag systems available and explore how they provide enhanced safety for truck drivers. Let’s dive in!

1. Frontal Air Bags: Just like in cars, frontal air bags are the most common type used in truck air bag systems. These air bags are typically located in the steering wheel and dashboard area and deploy in the event of a frontal collision. They provide cushioning and can greatly reduce the impact on the driver and front passenger.

2. Side Air Bags: Side air bags are designed to protect occupants in the event of a side impact collision. These air bags are usually located in the door panels or seatbacks and deploy rapidly to create a protective barrier between the occupants and the intruding object or vehicle. They can significantly reduce the risk of head and chest injuries.

3. Curtain Air Bags: Curtain air bags, also known as roof-mounted air bags, provide protection to the head area in the event of a rollover or side impact collision. These air bags deploy from the roof lining or overhead console and create a protective curtain along the windows. Curtain air bags are particularly effective in preventing head injuries and keeping the occupants safely inside the truck.

4. Seat Belt Air Bags: Seat belt air bags are a relatively newer addition to truck air bag systems. These innovative systems incorporate air bags into the seat belts themselves. In the event of a collision, the seat belt air bags rapidly inflate to provide additional restraint and distribute the forces more evenly across the occupant’s body. This can reduce the risk of severe injuries, especially in high-impact accidents.

5. Knee Air Bags: Knee air bags are designed to protect the driver and front passenger’s knees and lower legs in a frontal collision. These air bags are typically located in the lower part of the dashboard and deploy to provide cushioning and restraint for the lower extremities. Knee air bags can help prevent fractures and other lower body injuries.

| Type of Air Bag System | Main Purpose |

|---|---|

| Frontal Air Bags | Protection in frontal collisions |

| Side Air Bags | Protection in side impact collisions |

| Curtain Air Bags | Protection in rollovers and side impact collisions |

| Seat Belt Air Bags | Enhanced seat belt restraint and force distribution |

| Knee Air Bags | Protection for knees and lower legs |

Each type of truck air bag system serves a specific purpose and works in harmony to provide comprehensive protection in different types of accidents. The combination of these different air bag systems greatly enhances the safety of truck occupants and helps mitigate the risk of severe injuries.

Remember, having the right truck air bag system for your vehicle is crucial for maximum safety. Consult with experts or your vehicle manufacturer to ensure you have the appropriate air bag system installed in your truck. Stay safe on the road!

Common issues with truck air bag systems

Truck air bag systems are an important safety feature in commercial vehicles. They are designed to provide additional protection to the driver and passengers in the event of a collision or sudden impact. However, like any mechanical system, truck air bag systems can experience various issues over time. In this blog post, we will discuss some common issues that truck air bag systems may encounter and explore possible solutions to these problems.

One of the most common issues with truck air bag systems is a faulty sensor. The sensor is responsible for detecting a sudden impact or collision and triggering the deployment of the air bag. If the sensor malfunctions, it may fail to detect an accident or deploy the air bag at the wrong time. This can be extremely dangerous for the driver and passengers. To fix this issue, the faulty sensor needs to be replaced with a new one that is compatible with the truck’s air bag system.

Another common issue is a leak in the air bag system. Over time, the air bags may develop leaks, causing them to lose air pressure. As a result, the air bags may not inflate properly during a collision, reducing their effectiveness in protecting the occupants of the truck. To resolve this issue, the damaged air bags should be replaced with new ones to ensure proper inflation and maximum safety.

Furthermore, electrical problems can also arise in truck air bag systems. Worn-out or damaged wiring can interfere with the communication between the sensor, control module, and the air bags. As a result, the air bags may not function as intended. To address this issue, it is essential to inspect the wiring connections regularly and replace any defective wires to ensure proper communication and functioning of the truck air bag system.

For a quick overview, here is a list summarizing the common issues with truck air bag systems:

- Faulty sensor

- Leak in the air bag system

- Electrical problems

In conclusion, while truck air bag systems play a vital role in enhancing occupant safety, they can experience certain issues over time. It is crucial for truck owners and operators to be aware of these common issues and take necessary measures to address them promptly. Regular maintenance, inspection, and repair of the truck air bag system are necessary to ensure optimal performance and safety on the road.

Maintenance and troubleshooting tips for truck air bag systems

Maintenance and Troubleshooting Tips for Truck Air Bag Systems

Truck air bag systems are crucial for ensuring the safety of both drivers and passengers while on the road. These systems play a major role in preventing severe injuries during accidents, making it essential to keep them in optimal condition. Regular maintenance and troubleshooting are necessary to ensure that the air bag system functions effectively when needed. In this blog post, we will discuss some important tips for maintaining and troubleshooting truck air bag systems, which will help ensure their reliability and effectiveness.

Regular Inspection:

The first step in maintaining truck air bag systems is conducting regular inspections. Inspect the air bag sensors and wiring for any signs of damage or wear. Ensure that the sensors are properly secured and that there are no loose connections. Additionally, check the condition of the air bag module and inflator. Look for any signs of corrosion or physical damage that may affect their functionality. Any issues found during the inspection should be addressed promptly to prevent potential malfunctions.

Check for Error Codes:

Modern truck air bag systems are equipped with diagnostic tools that can provide error codes for troubleshooting. If your truck’s air bag system has a built-in diagnostic function, connect the diagnostic tool to the system and retrieve the error codes. These error codes can provide valuable insights into the specific issues affecting the system. Once obtained, refer to the system’s manual or consult a professional to understand and address the identified problems effectively.

Replace Damaged Components:

If any components of the truck air bag system are damaged, they should be replaced immediately. Damaged sensors, wiring, or modules can compromise the overall functionality of the system, increasing the risk of failure during an accident. It is important to source genuine replacement parts and ensure proper installation. Consult the manufacturer’s guidelines and, if necessary, seek assistance from a qualified technician to ensure the correct replacement of damaged components.

Regular Battery Maintenance:

Truck air bag systems rely on electrical power to function correctly. Therefore, maintaining the battery in good condition is crucial. Regularly check the battery terminals to ensure they are clean and securely connected. It is also important to monitor the battery’s voltage and replace it if it shows signs of deterioration. A weakened battery may not provide enough power to deploy the air bags effectively, compromising the system’s performance in critical situations.

Conclusion:

Maintaining and troubleshooting truck air bag systems is essential for their proper functionality and reliability. Regular inspections, checking for error codes, replacing damaged components, and maintaining the battery are some of the key tips for effective maintenance. By following these guidelines and promptly addressing any identified issues, truck owners can ensure the safety of themselves and their passengers while on the road.

Upgrading your truck air bag system

The truck air bag system is an essential safety feature that helps protect both the driver and passengers in the event of an accident. However, like any other component in a vehicle, the air bag system can be upgraded to enhance its performance and reliability. Upgrading your truck air bag system can offer several benefits, including increased safety, improved handling, and enhanced towing capabilities.

One key component of upgrading your truck air bag system is replacing the standard air bags with heavy-duty air bags. These heavy-duty air bags are designed to withstand higher pressures and provide better support for heavy loads. By installing heavy-duty air bags, you can significantly enhance the suspension system of your truck and improve its overall stability, especially when carrying heavy cargo or towing trailers.

Another important upgrade for your truck air bag system is the addition of an onboard compressor. An onboard compressor allows you to adjust the air pressure in the air bags as needed, providing better control over your vehicle’s suspension. With an onboard compressor, you can easily increase or decrease the air pressure in the air bags to compensate for different load conditions, ensuring a smooth and comfortable ride.

In addition to heavy-duty air bags and an onboard compressor, you may also consider upgrading other components of your truck air bag system, such as the control module and sensors. The control module is responsible for monitoring various parameters and deploying the air bags in the event of a collision. Upgrading the control module can improve its responsiveness and accuracy, ensuring timely deployment of the air bags when needed. Similarly, upgrading the sensors can enhance their sensitivity and accuracy in detecting potential collisions, providing you with an extra layer of safety.

In summary, upgrading your truck air bag system can greatly improve the safety and performance of your vehicle. By installing heavy-duty air bags, an onboard compressor, and upgrading other components such as the control module and sensors, you can enhance the suspension system, improve handling, and ensure timely deployment of the air bags. If you use your truck for heavy-duty purposes, such as towing or carrying heavy loads, upgrading your air bag system is definitely a worthwhile investment.

| Benefits of Upgrading Your Truck Air Bag System |

|---|

| Increased safety |

| Improved handling |

| Enhanced towing capabilities |

| Better control over suspension |

| Smooth and comfortable ride |

| Timely deployment of air bags |