Introduction to Air-Assisted Truck Ride Quality

When it comes to the comfort and stability of truck rides, air suspension systems play a crucial role. With the increasing demand for enhanced ride quality, truck drivers are turning to air-assisted rides as a solution. In this blog post, we will delve into the importance of ride quality and how air suspension systems contribute to the overall experience. We will also explore the benefits of air-assisted suspension for truck drivers, including improved load handling and safety. Moreover, we will discuss the maintenance and troubleshooting of air-assisted rides and look into the future of air-assisted truck ride quality. Get ready to embark on a journey to discover the world of air-assisted truck rides.

Introduction to Air-Assisted Truck Ride Quality

The ride quality of a truck plays a crucial role in the overall comfort and safety of drivers and passengers. One technology that has significantly improved ride quality is air-assisted suspension systems. These innovative systems have become increasingly popular in the trucking industry due to their ability to enhance comfort, stability, and load handling capabilities.

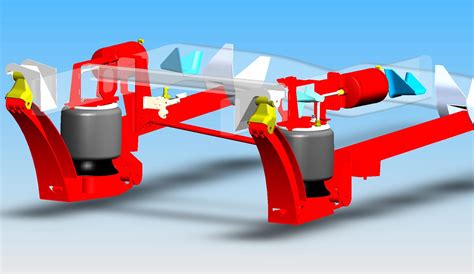

Trucks equipped with air-assisted suspension systems provide a smoother ride compared to traditional suspension systems. The key component of these systems is the use of air springs or airbags, which are located between the frame and the axle of the truck. These airbags are filled with compressed air, allowing the suspension to adjust and adapt to different road conditions and load weights. The result is a more comfortable and controlled ride, reducing driver fatigue and improving overall safety.

One of the main benefits of air-assisted suspension systems is their ability to improve load handling capabilities. The adjustability of airbags allows for proper weight distribution, reducing the strain on the suspension and increasing the stability of the truck. This is particularly important for trucks that frequently carry heavy loads or operate on uneven terrain. By providing a more stable and balanced ride, air-assisted suspension systems help to prevent excessive wear and tear on the truck’s components.

- Enhanced comfort and stability

- Reduced driver fatigue

- Improved load handling capabilities

- Increased safety

Air-assisted suspension systems also offer several advantages over traditional suspension systems. Unlike traditional systems, air-assisted suspension can be easily adjusted to accommodate different loads or road conditions. This flexibility allows drivers to fine-tune the suspension to their specific needs, resulting in a more comfortable and personalized ride experience.

Maintenance and troubleshooting of air-assisted truck rides are relatively straightforward. Regular inspection of the airbags, valves, and compressor is essential to ensure proper functioning of the system. Any signs of leaks or damage should be addressed immediately to prevent potential issues or failures. Troubleshooting techniques such as checking air pressure levels and inspecting for any abnormalities can help identify and resolve any problems.

| Air-Assisted Suspension Systems | Traditional Suspension Systems |

|---|---|

| Adjustable and customizable | Fixed and limited adjustment |

| Enhanced comfort and stability | Less comfort and stability |

| Improved load handling capabilities | Less load handling capabilities |

The future of air-assisted truck ride quality looks promising, with ongoing advancements in suspension technology. Manufacturers continue to refine and optimize air-assisted suspension systems to provide even greater levels of comfort, stability, and performance. As the demand for smooth and efficient rides increases, it is likely that air-assisted suspension systems will become even more prevalent in the trucking industry.

Understanding the Importance of Ride Quality

Ride quality refers to the comfort, smoothness, and stability experienced by vehicle occupants while driving. It plays a crucial role in ensuring a comfortable and enjoyable ride for both the driver and passengers. Ride quality is especially important in long-haul trucking, where drivers spend extended periods on the road.

The importance of ride quality cannot be overstated. It directly affects the driver’s physical well-being and mental alertness during long hours behind the wheel. A smooth and comfortable ride reduces driver fatigue, allowing them to stay focused and alert, ultimately improving road safety. Additionally, a comfortable ride also enhances the overall experience for passengers, making their journey more pleasant.

Moreover, ride quality affects the durability and longevity of the truck itself. Rough roads and harsh driving conditions can lead to increased wear and tear on the vehicle’s components, resulting in frequent repairs and maintenance. By prioritizing ride quality, truck owners can minimize the risk of mechanical failures, optimize vehicle performance, and reduce overall maintenance costs.

- Enhanced driver comfort and reduced fatigue

- Improved road safety

- Longer vehicle lifespan

- Decreased maintenance expenses

| Factors Influencing Ride Quality | Description |

|---|---|

| Suspension System | The type and quality of the suspension system significantly impact ride quality. Air suspension systems are known for their ability to provide a smoother and more comfortable ride compared to traditional suspension systems. |

| Tire Selection | The choice of tires plays a crucial role in determining ride quality. Tires with a higher aspect ratio and better shock absorption capabilities can improve overall comfort and reduce road noise. |

| Vehicle Weight | Overloading a truck beyond its weight capacity can lead to compromised ride quality. It is important to adhere to recommended weight limits to ensure a smoother ride. |

| Road Conditions | The condition of the road itself, including its smoothness, pot holes, and bumps, can significantly impact ride quality. Well-maintained roads contribute to a smoother and more comfortable driving experience. |

In conclusion, understanding the importance of ride quality is essential for truck owners, drivers, and passengers alike. Prioritizing ride comfort and stability not only improves the overall driving experience but also enhances road safety and reduces maintenance costs. By investing in advanced technologies such as air-assisted suspension systems and selecting appropriate tires, truck owners can optimize ride quality and ensure a smooth journey for all.

The Role of Air Suspension Systems in Truck Ride Quality

When it comes to truck ride quality, one crucial factor that cannot be overlooked is the role of air suspension systems. These systems play a significant role in enhancing the comfort, stability, and overall performance of trucks on the road. By utilizing air springs and adjusting the air pressure, air suspension systems can effectively absorb shocks, dampen vibrations, and provide a smoother ride.

The importance of ride quality in trucks cannot be overstated. A comfortable and stable ride not only improves driver satisfaction but also contributes to increased productivity and safety. With air suspension systems, truck drivers can experience reduced driver fatigue, improved control and stability, and increased load-carrying capacity. Additionally, these systems help minimize the wear and tear on the truck’s components, leading to longer vehicle lifespan and lower maintenance costs.

Let’s take a closer look at how air suspension systems improve ride quality in trucks. Firstly, the use of air springs provides a customizable and adjustable suspension solution. The air pressure inside the springs can be adjusted according to the load being carried, ensuring optimal performance and ride comfort. Additionally, air suspension systems can automatically maintain a level ride height, compensating for shifts in weight distribution and offering consistent handling and stability.

- Improved Comfort: Air suspension systems excel at providing a smooth and comfortable ride by actively absorbing road shocks, vibrations, and bumps. The flexible and adjustable nature of air springs allows for superior cushioning, reducing driver fatigue and enhancing overall comfort.

- Enhanced Safety and Stability: By evenly distributing the weight across all wheels, air suspension systems improve the stability and handling of trucks. This results in reduced swaying, improved traction, and better control, especially during cornering, braking, and sudden maneuvers.

- Increased Load-Carrying Capacity: Air-assisted suspension systems can handle heavier loads compared to traditional suspension systems. The ability to adjust the air pressure in the springs ensures that the truck operates within its optimal weight limits, maximizing load-carrying capacity without compromising safety or ride quality.

In comparison to traditional suspension systems, air-assisted suspension offers several advantages. The adjustable nature of air springs allows for quick and easy load adjustments, making it ideal for applications that involve varying load sizes. Moreover, air suspension systems deliver a more stable and comfortable ride, reducing the risk of cargo damage and driver fatigue. This makes them particularly beneficial for long-haul trucking and transportation industries.

| Traditional Suspension Systems | Air-Assisted Suspension Systems |

|---|---|

| Fixed suspension settings | Adjustable air pressure for customization |

| Less flexibility in adjusting for varying loads | Easy load adjustments based on cargo weight |

| Greater risk of cargo damage and driver fatigue | Enhanced stability and comfort for driver and cargo |

To ensure the continued performance and reliability of air suspension systems, regular maintenance and troubleshooting are essential. Proper inspection and servicing of air springs, air lines, valves, and compressors can help identify and address any potential issues before they escalate. By following manufacturers’ guidelines and seeking professional assistance when needed, truck owners can maintain the optimal functioning of their air suspension systems.

The future of truck ride quality lies in the further advancement of air-assisted suspension systems. With ongoing technological developments, we can expect enhanced integration of sensors, predictive analytics, and automated control systems. These advancements will enable even more precise and efficient load adjustments, improved driver assistance features, and ultimately, revolutionize the way we perceive truck ride quality.

Enhancing Comfort and Stability with Air-Assisted Rides

When it comes to truck ride quality, comfort and stability are two key factors that every driver desires. A smooth and stable ride not only enhances the driver’s comfort but also ensures their safety on the road. One technology that has revolutionized the truck ride experience is air-assisted rides, which utilize air suspension systems to provide superior comfort and stability.

Air suspension systems are designed to replace traditional steel springs with airbags or air springs. These airbags are filled with compressed air, allowing them to adjust and inflate based on the weight and load of the truck. This dynamic support system actively responds to changes in road conditions, ensuring a more comfortable and stable ride.

One of the key benefits of air-assisted rides is their ability to enhance comfort. The adjustable nature of airbags provides a smooth and cushioned ride, reducing the impact of bumps, potholes, and uneven road surfaces. The air springs absorb and distribute the shocks, minimizing any vibrations or jolts that would be felt in a truck equipped with traditional suspension systems.

Benefits of Air-Assisted Suspension for Truck Drivers

When it comes to driving heavy-duty trucks, one of the top priorities for truck drivers is ensuring a smooth and comfortable ride. The impact of a bumpy ride can be felt not just by the driver, but also by the cargo being transported. This is where air-assisted suspension systems come into play, offering a range of benefits specifically designed to enhance the ride quality for truck drivers.

First and foremost, one of the key advantages of air-assisted suspension for truck drivers is the improved comfort it provides. By using air springs, these systems are able to absorb shocks and vibrations from the road, resulting in a smoother and more cushioned ride. This is especially important for long-haul truck drivers who spend extended periods of time on the road.

In addition to increased comfort, air-assisted suspension also plays a crucial role in enhancing stability. The use of air springs allows for better weight distribution, which helps to minimize body roll and sway. This not only improves the handling of the truck but also reduces the likelihood of accidents or rollovers, ultimately enhancing the safety of both the driver and the cargo being transported.

- Improved comfort

- Enhanced stability

- Reduced maintenance

- Increased payload capacity

- Better fuel efficiency

| Benefit | Description |

|---|---|

| Improved comfort | Air-assisted suspension systems provide a smoother and more comfortable ride, reducing driver fatigue and improving overall driving experience. |

| Enhanced stability | The use of air springs improves weight distribution and reduces body roll and sway, resulting in increased stability on the road. |

| Reduced maintenance | By absorbing shocks and vibrations, air-assisted suspension systems help to minimize wear and tear on other components of the truck, reducing maintenance needs. |

| Increased payload capacity | With the improved weight distribution provided by air-assisted suspension, truck drivers can safely carry heavier loads without compromising stability or safety. |

| Better fuel efficiency | The enhanced stability and reduced resistance offered by air-assisted suspension systems can contribute to improved fuel efficiency, saving truck drivers money on fuel costs. |

In addition to the aforementioned benefits, air-assisted suspension systems also help to reduce the maintenance requirements of heavy-duty trucks. By absorbing shocks and vibrations, these systems help to minimize wear and tear on other components such as tires, axles, and suspension parts. This not only reduces maintenance costs but also extends the lifespan of these components, ensuring longer-lasting and more reliable performance.

Furthermore, air-assisted suspension systems can increase the payload capacity of trucks. The improved weight distribution provided by air springs allows truck drivers to safely carry heavier loads without compromising stability or safety. This can be particularly advantageous for industries that require the transportation of bulky or heavy goods.

Lastly, air-assisted suspension systems contribute to better fuel efficiency. By improving stability and reducing resistance, these systems help to optimize the truck’s aerodynamics, resulting in reduced fuel consumption. This not only benefits truck drivers financially but also has a positive impact on the environment by reducing carbon emissions.

In summary, the benefits of air-assisted suspension for truck drivers are numerous. From enhanced comfort and stability to reduced maintenance and increased payload capacity, these systems are a valuable addition to heavy-duty trucks. Not only do they provide a more comfortable and safer ride for the driver, but they also contribute to cost savings and environmental sustainability. For truck drivers seeking to improve their overall driving experience, investing in air-assisted suspension systems is undoubtedly a wise choice.

Improving Load Handling and Safety with Air-Assisted Rides

The use of air-assisted rides in trucks can significantly improve load handling and safety. Trucks are often required to transport heavy loads over long distances, and traditional suspension systems may not provide the necessary stability and support. Air-assisted rides utilize air springs or airbags that can be adjusted to accommodate different load sizes, ensuring optimal weight distribution and improved handling.

One of the key benefits of air-assisted rides is their ability to enhance load carrying capacity and stability. Unlike traditional suspension systems, which rely on steel springs and shocks, air-assisted rides use compressed air to support the load. This allows for better shock absorption and reduction of vibrations, which can reduce the risk of load shifts and improve overall stability during transportation.

In addition to improved load handling, air-assisted rides also contribute to enhanced safety on the road. The adjustability of air springs allows truck drivers to fine-tune the suspension system based on the specific load requirements. This ensures that the truck maintains the proper ride height, preventing excessive bouncing and swaying. Stable load handling, especially during cornering and sudden maneuvers, minimizes the risk of rollovers and ensures safer transportation of goods.

Air-Assisted Suspension vs. Traditional Suspension Systems

When it comes to choosing the right suspension system for a truck, one of the major decisions that truck owners and operators have to make is whether to go for air-assisted suspension or traditional suspension systems. Both options have their own set of advantages and disadvantages, and it ultimately depends on the specific needs and preferences of the truck driver. In this blog post, we will explore the differences between air-assisted suspension and traditional suspension systems, and discuss how each option can impact the overall ride quality and performance of a truck.

Benefits of Air-Assisted Suspension:

1. Improved Comfort: One of the key advantages of air-assisted suspension systems is the enhanced level of comfort they provide. The use of air springs allows for a smoother and more cushioned ride, reducing the impact of bumps and vibrations on the driver and the cargo.

2. Adjustable Ride Height: Another major advantage of air-assisted suspension systems is the ability to adjust the ride height of the truck. This can be particularly useful when it comes to loading and unloading cargo, as well as navigating different terrains. The adjustable ride height also allows for better maneuverability and stability.

Drawbacks of Air-Assisted Suspension:

1. Cost: One of the main drawbacks of air-assisted suspension systems is the higher initial cost compared to traditional suspension systems. The installation and maintenance of air springs and related components can be more expensive.

2. Complexity: Air-assisted suspension systems are generally more complex than traditional suspension systems. This complexity can lead to a higher risk of component failure and the need for more frequent maintenance and repairs.

| Aspect | Air-Assisted Suspension | Traditional Suspension |

|---|---|---|

| Ride Quality | Improved comfort and stability | Less cushioning and damping |

| Adjustability | Can adjust ride height | Fixed ride height |

| Cost | Higher initial cost | Lower initial cost |

| Complexity | More complex system | Simpler system |

In conclusion, the choice between air-assisted suspension and traditional suspension systems depends on various factors such as ride comfort, adjustability, cost, and complexity. While air-assisted suspension offers improved comfort and adjustability, it comes at a higher cost and complexity compared to traditional suspension systems. Truck owners and operators should carefully evaluate their specific needs and priorities before making a decision. Ultimately, a well-maintained and properly chosen suspension system can significantly enhance the ride quality and overall performance of a truck.

Maintenance and Troubleshooting of Air-Assisted Truck Rides

In order to ensure a smooth and efficient operation of air-assisted truck rides, regular maintenance and troubleshooting are essential. Neglecting these aspects can lead to various issues and potential safety hazards. In this blog post, we will explore the importance of maintenance for air-assisted truck rides and provide some troubleshooting tips to keep your rides in optimal condition.

Maintenance plays a crucial role in the longevity and performance of air-assisted truck rides. One of the primary maintenance tasks is to regularly inspect the air suspension system for any signs of wear and tear. This includes checking the air springs, valves, and compressor for leaks, cracks, or other damage. Additionally, it is important to ensure that the air pressure is properly adjusted according to the manufacturer’s guidelines. Proper maintenance not only extends the lifespan of the system but also ensures a safe and comfortable ride.

Troubleshooting is another aspect that cannot be overlooked when it comes to air-assisted truck rides. One common issue that truck drivers may encounter is an uneven or sagging ride. This could be an indication of a failing air spring or a leak in the system. In such cases, it is important to inspect and replace any faulty components to restore the ride quality. Another troubleshooting tip is to regularly clean and inspect the air filters to prevent any obstructions that could affect the performance of the air suspension system.

- Maintain proper air pressure

- Regularly inspect for leaks and damage

- Inspect and replace faulty components

- Clean and inspect air filters

It is worth mentioning that preventive maintenance is always better than reactive troubleshooting. By implementing a regular maintenance schedule and following the manufacturer’s recommendations, you can prevent potential issues and avoid costly repairs in the long run. Additionally, seeking professional assistance can provide further guidance and expertise for the maintenance and troubleshooting of air-assisted truck rides.

| Common Maintenance Tasks | Troubleshooting Tips |

|---|---|

| Inspect air springs, valves, and compressor | Address uneven or sagging ride promptly |

| Adjust air pressure according to guidelines | Clean and inspect air filters regularly |

| Replace faulty components | Seek professional assistance if needed |

Maintenance and troubleshooting are essential for ensuring the smooth operation and longevity of air-assisted truck rides. By following the proper maintenance procedures and promptly addressing any issues that arise, you can enhance safety, stability, and comfort for both the driver and the passengers. Remember, a well-maintained air suspension system is key to a successful and hassle-free journey.

The Future of Air-Assisted Truck Ride Quality

The future of air-assisted truck ride quality is an exciting and promising one. With advancements in technology and a growing focus on driver comfort and safety, air suspension systems are expected to play a significant role in improving the overall ride experience for truck drivers.

One of the key benefits of air-assisted suspension systems is the ability to adjust the ride height and stiffness of the truck. This feature allows drivers to customize their ride based on the load they are carrying and the road conditions they encounter. With the use of sensors and computer-controlled algorithms, the suspension system can automatically adjust to provide optimal stability and comfort.

Another important aspect of the future of air-assisted truck ride quality is the integration of smart technologies. The use of sensors and data analytics can provide real-time information about the condition of the road, the load distribution, and the driver’s behavior. This data can be used to make proactive adjustments to the suspension system, enhancing safety and reducing the risk of accidents.

| Benefits of Air-Assisted Suspension for Truck Drivers |

|---|

| 1. Improved ride comfort |

| 2. Enhanced stability |

| 3. Customizable ride settings |

| 4. Increased safety |

| 5. Reduced driver fatigue |

In addition to comfort and safety, the future of air-assisted truck ride quality also holds promise for reducing maintenance costs. Traditional suspension systems often require frequent maintenance and repairs, leading to downtime and increased expenses. On the other hand, air suspension systems are designed with durability in mind and can withstand harsh conditions, reducing the need for frequent repairs and replacements.

As technology continues to advance, the future of air-assisted truck ride quality will likely see even more innovative features. This could include the integration of autonomous driving technologies, where the suspension system can communicate with other autonomous systems in the truck to provide a seamless and optimized ride experience.

In conclusion, the future of air-assisted truck ride quality looks promising. With the ability to customize the ride, integrate smart technologies, and reduce maintenance costs, air suspension systems are set to revolutionize the trucking industry. Truck drivers can look forward to a more comfortable, stable, and efficient ride, ultimately leading to improved safety and productivity on the road.