Introduction: Understanding the Role of a Semi Truck Air Dryer

As a truck driver, it is essential to have a properly functioning air braking system to ensure your safety on the road. One crucial component of this system is the air dryer, which plays a vital role in removing moisture and contaminants from the compressed air before it reaches the brakes. In this blog post, we will explore the importance of a properly functioning air dryer and discuss common signs of a faulty one. Furthermore, we will provide steps on how to replace an air dryer, maintenance tips to extend its lifespan, and tips for choosing the right air dryer for your semi truck. Additionally, we will highlight the benefits of regular air dryer inspections and servicing. By understanding the role and importance of a semi truck air dryer, you can ensure a safer and more efficient journey on the road.

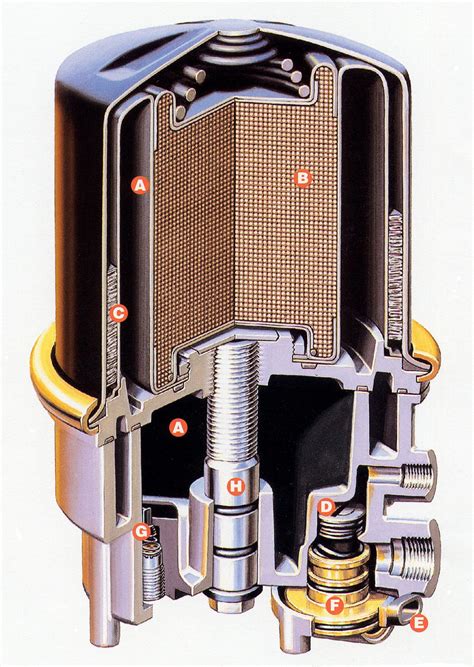

What is a semi truck air dryer?

A semi truck air dryer is a crucial component of the vehicle’s air brake system. It is responsible for removing moisture and contaminants from the compressed air that is used to operate the brakes. Without a properly functioning air dryer, moisture can accumulate in the system, leading to a range of issues such as reduced braking efficiency and potential damage to other components.

One of the main functions of a semi truck air dryer is to prevent moisture from entering the brake lines. Moisture in the brake system can cause the brake lines to freeze in cold temperatures, resulting in a loss of braking power. Additionally, moisture can corrode the brake lines and other components, leading to costly repairs and potential safety hazards.

Another important role of the air dryer is to remove contaminants from the compressed air. These contaminants can include oil, dirt, and debris that can negatively impact the system’s performance. By filtering out these contaminants, the air dryer helps to ensure that only clean, dry air is delivered to the brakes.

- Reduces moisture in the brake system

- Prevents freezing of brake lines in cold temperatures

- Filters out contaminants for optimal performance

| Key Benefits of a Semi Truck Air Dryer |

|---|

| 1. Improved braking efficiency |

| 2. Extended lifespan of brake components |

| 3. Reduced risk of brake failure |

| 4. Cost savings on repairs and maintenance |

| 5. Enhanced safety for the driver and others on the road |

Importance of a properly functioning air dryer

Having a properly functioning air dryer is crucial for the efficient operation of a semi truck. An air dryer, as the name suggests, is a device that removes moisture and contaminants from the air system of a vehicle. It plays a vital role in maintaining the overall performance and safety of the vehicle.

A properly functioning air dryer is essential for several reasons. Firstly, it helps to prevent moisture from entering the truck’s air system. Moisture can cause corrosion and damage to various components of the system, leading to expensive repairs. Additionally, moisture in the air system can freeze during cold weather conditions, resulting in reduced braking capabilities.

Another important reason for ensuring a properly functioning air dryer is to maintain air system efficiency. Moisture and contaminants in the air can cause air valves and seals to stick, resulting in air leaks. These leaks can lead to reduced brake effectiveness, impaired suspension performance, and loss of air pressure in the system. Regularly inspecting and servicing the air dryer helps to prevent such issues and ensures the proper functioning of the vehicle’s air system.

In order to identify if an air dryer is faulty, it is important to recognize certain common signs. These signs include excessive moisture in the air tanks, reduced air pressure for braking, longer braking distances, and noisy operation of the air compressor. If you notice any of these signs, it is recommended to have the air dryer inspected and replaced if necessary.

- Excessive moisture in air tanks

- Reduced air pressure for braking

- Longer braking distances

- Noisy operation of the air compressor

Replacing a faulty air dryer is a relatively straightforward process that can be done with basic tools and some technical knowledge. However, if you are unsure or don’t have the necessary skills, it is always best to consult a professional. Steps to replace a semi truck air dryer include depressurizing the air system, removing the old air dryer, installing the new air dryer, and testing the system for proper operation.

Maintaining the air dryer is essential for extending its lifespan and ensuring continued optimal performance. Some maintenance tips for the air dryer include regularly inspecting and cleaning the air dryer cartridge, checking for air leaks, inspecting the system for moisture and contaminants, and replacing the desiccant material at recommended intervals.

| Importance of a properly functioning air dryer: |

|---|

| Prevents moisture and contaminants from entering the air system |

| Maintains air system efficiency |

| Prevents air leaks and loss of air pressure |

| Ensures optimal braking performance and overall safety |

Choosing the right air dryer for your semi truck is also crucial. Factors to consider include the truck’s air system capacity, desired drying capacity, compatibility with the truck’s existing components, and manufacturer recommendations. Consulting with a professional or referring to the truck’s manual can help ensure the selection of the most suitable air dryer for your specific needs.

Regular air dryer inspections and servicing offer numerous benefits. Firstly, they help to identify and address any potential issues early on, preventing more serious and costly problems down the line. Additionally, regular inspections and servicing help to maintain the safety and performance of the air system, ensuring the driver and other road users are protected.

In conclusion, the importance of a properly functioning air dryer cannot be overstated. It is a critical component of a semi truck’s air system, responsible for removing moisture and contaminants. By ensuring the air dryer is in good condition, truck owners can maintain optimal braking performance, prevent costly repairs, and ensure overall safety on the road.

Common signs of a faulty air dryer

When it comes to maintaining the optimal performance of a semi truck, one crucial component to consider is the air dryer. The air dryer plays a vital role in removing moisture and contaminants from the air supply system, ensuring that the brakes and other pneumatic systems operate efficiently. However, like any other part, the air dryer can develop faults over time, leading to potential issues and compromising safety on the road. In this blog post, we will discuss some common signs of a faulty air dryer that every truck driver should be aware of.

1. Increased Air Pressure

One of the first signs of a faulty air dryer is an increase in air pressure. If you notice that the air gauge is displaying a higher pressure level than usual, it could be a clear indication that the air dryer is not functioning properly. This can happen when the desiccant material in the air dryer becomes saturated and unable to effectively absorb moisture. As a result, excessive pressure builds up in the air system, potentially leading to brake malfunctions or other pneumatic issues.

2. Excessive Moisture

If you notice excessive moisture in the air tanks or air lines, it is another sign that your air dryer may be faulty. The primary function of an air dryer is to remove moisture from the compressed air supply, preventing water from entering the brake system. When the air dryer is not working correctly, moisture can bypass the desiccant and accumulate in the air tanks. This can lead to corrosion, reduced brake efficiency, and even freezing in cold weather conditions.

3. Noisy Operation

Unusual noises coming from the air dryer during operation can indicate a fault in the system. If you hear rattling, hissing, or any other unusual sounds, it could mean that the air dryer’s components, such as the purge valve or check valve, are malfunctioning. These components are responsible for controlling the flow of air and maintaining optimal pressure levels. When they fail, it can cause disruptions in the air supply, affecting the overall performance of the braking system.

4. Delayed Brake Response

A faulty air dryer can also lead to delayed brake response. If you find that your brakes are taking longer to engage or if there is a noticeable delay in braking, it could be a sign that the air dryer is not supplying dry and clean air to the brake system. Moisture or contaminants in the air lines can interfere with the proper functioning of the brake valves, leading to compromised braking efficiency. This can pose a significant safety risk, especially during emergency braking situations.

Overall, it is essential for truck drivers to be aware of these common signs of a faulty air dryer. Regular inspection and maintenance of the air dryer can help prevent potential issues and ensure the safe operation of the semi truck. If you notice any of these signs, it is crucial to address the problem promptly by seeking professional assistance. By maintaining a properly functioning air dryer, you can enhance the overall safety and performance of your semi truck on the road.

Steps to replace a semi truck air dryer

A semi truck air dryer is an essential component of the truck’s air braking system. It plays a crucial role in removing moisture and contaminants from the compressed air before it reaches the valves and other brake components. Over time, the air dryer may become worn out or develop faults, necessitating its replacement. In this blog post, we will discuss the steps involved in replacing a semi truck air dryer.

Before beginning the replacement process, gather all the necessary tools and equipment, including a new air dryer, socket wrenches, screwdrivers, and safety goggles. Begin by relieving the air pressure in the system by draining the air tanks. Locate the air dryer, which is typically mounted near the compressor or on the frame rail.

Next, disconnect the air lines connected to the air dryer. Use the appropriate wrenches or socket wrenches to loosen the fittings and carefully remove the lines. It is important to note which line goes where to ensure proper reinstallation later. Inspect the lines for any signs of wear or damage and replace them if necessary.

Maintenance tips for extending the air dryer’s lifespan

The air dryer in a semi truck plays a crucial role in maintaining the overall performance and safety of the vehicle’s braking system. It functions by removing moisture and contaminants from the compressed air system, preventing the build-up of rust, corrosion, and other potential issues. To ensure that your air dryer operates efficiently and has an extended lifespan, it is essential to follow some maintenance tips.

Regular Inspection: One of the primary maintenance practices for extending the air dryer’s lifespan is performing regular inspections. This involves visually checking the air dryer for any signs of leaks, corrosion, or damage. Additionally, inspect the air dryer’s mounting bracket, electrical connections, and hoses for any wear and tear. By conducting routine inspections, you can catch potential issues early on and address them before they escalate into significant problems.

Clean the Air Dryer: Another vital maintenance tip is to clean the air dryer regularly. Over time, moisture and contaminants can accumulate in the air dryer’s internal components, affecting its performance. Use a clean cloth or a soft-bristle brush to remove any dirt, debris, or oil build-up from the surface of the air dryer. Ensure that the air dryer is completely dry before reinstalling it to prevent any moisture-related issues.

Replace Desiccant Cartridge: The desiccant cartridge is the part of the air dryer that absorbs moisture. However, over time, it can become saturated and lose its effectiveness. As part of your maintenance routine, it is important to replace the desiccant cartridge periodically. Consult your vehicle’s manual or the manufacturer’s instructions for the recommended replacement interval. By replacing the desiccant cartridge as recommended, you can ensure that the air dryer continues to remove moisture efficiently, extending its lifespan.

Follow Proper Installation Procedures: When replacing or reinstalling the air dryer, it is crucial to follow the correct installation procedures. Ensure that all connections are tightened properly and that the air dryer is securely mounted. Improper installation can lead to leaks, vibration, or other malfunctions, reducing the lifespan of the air dryer. Consult the manufacturer’s guidelines or seek professional assistance to ensure the proper installation of the air dryer.

Perform Regular System Checks: To maintain the air dryer’s efficiency and extend its lifespan, it is important to perform regular checks of the entire compressed air system in your semi truck. Inspect the air tanks, valves, lines, and other components for any signs of leaks, damage, or contamination. Addressing any issues promptly can help prevent excessive strain on the air dryer, allowing it to function optimally for a longer period of time.

By following these maintenance tips, you can help extend the lifespan of your semi truck’s air dryer, ensuring that it continues to operate effectively and contribute to the overall safety of your vehicle. Regular inspections, cleaning, desiccant cartridge replacement, proper installation procedures, and system checks are all essential aspects of air dryer maintenance that should not be overlooked.

Choosing the right air dryer for your semi truck

A semi truck air dryer is an essential component of the truck’s braking system. It plays a crucial role in removing moisture and contaminants from the compressed air, ensuring that the brake system operates efficiently and safely. Choosing the right air dryer for your semi truck is vital to maintain the optimal performance of the braking system and prevent potential issues.

When selecting an air dryer for your semi truck, there are several factors to consider. Firstly, you need to determine the appropriate size and capacity of the air dryer. The size of the air dryer should match the air volume requirements of your truck’s braking system. It is important to consult the manufacturer’s recommendations or seek professional advice to ensure the proper size selection.

Another critical factor to consider is the type of air dryer. There are two main types of air dryers commonly used in semi trucks: standard desiccant dryers and spin-on cartridge dryers. Standard desiccant dryers use a chemical desiccant to absorb moisture, while spin-on cartridge dryers incorporate a replaceable cartridge that simplifies maintenance.

Furthermore, it is important to consider the specific features and technologies offered by different air dryers. Some air dryers come equipped with advanced filtration systems to effectively remove contaminants, while others include integrated heater elements to prevent freezing in cold climates. Evaluating these features and selecting the ones that best suit your needs can significantly enhance the performance and reliability of your semi truck’s braking system.

Benefits of regular air dryer inspections and servicing

Regular air dryer inspections and servicing for semi trucks have numerous benefits that can greatly impact the overall performance and longevity of a vehicle. An air dryer is a vital component of a semi truck’s braking system, responsible for removing moisture from the compressed air that powers the brakes. Ensuring the proper functioning of the air dryer is essential for maintaining efficient and reliable braking, as well as preventing potential safety hazards on the road.

One of the key benefits of regular air dryer inspections and servicing is enhanced braking performance. Over time, moisture can accumulate in the air system, leading to corrosion of the brake components. This can result in reduced braking power and longer stopping distances, increasing the risk of accidents. By conducting regular inspections and servicing of the air dryer, any moisture buildup can be identified and eliminated, ensuring that the braking system functions at its optimal level.

Additionally, regular inspections and servicing of the air dryer can help to extend its lifespan. The components of an air dryer are subjected to high levels of thermal stress and continuous usage, which can cause wear and tear over time. By conducting routine maintenance, such as cleaning and lubricating the valves and replacing worn out parts, the air dryer can be kept in good condition, thereby prolonging its lifespan. This not only saves on costly repairs or replacements but also ensures the overall reliability of the vehicle.

In addition to improved performance and longevity, regular inspections and servicing can also contribute to cost savings. A faulty air dryer can lead to increased fuel consumption, as the compressor has to work harder to compensate for any loss of air pressure. By maintaining the air dryer in optimal condition, fuel efficiency can be maximized, resulting in savings on fuel expenses. Moreover, by detecting and addressing any potential issues early on, costly breakdowns or emergency repairs can be avoided, saving both time and money.

| Benefits of Regular Air Dryer Inspections and Servicing: | ||

|---|---|---|

| Enhanced braking performance | Extended lifespan of the air dryer | Cost savings through improved fuel efficiency and prevention of breakdowns |