Introduction:

The air dryer in a semi truck plays a crucial role in maintaining the overall efficiency and safety of the vehicle’s braking system. Understanding its importance, working mechanism, and the benefits of regular maintenance and cleaning will help truck drivers and fleet owners keep their vehicles in optimal condition. Moreover, knowing common problems and troubleshooting tips, as well as the advantages of upgrading to a new air dryer, can greatly enhance the performance of a semi truck. In this blog post, we will explore the various aspects of a semi truck air dryer, along with expert tips for maximizing its efficiency and guidelines for choosing the right air dryer for your specific needs.

What is a semi truck air dryer?

A semi truck air dryer is an important component of the vehicle’s braking system. It is designed to remove moisture and contaminants from the compressed air produced by the truck’s air compressor. The air dryer plays a crucial role in maintaining the performance and reliability of the braking system, which is essential for the safety of the truck and its driver.

One of the main purposes of a semi truck air dryer is to prevent moisture from reaching the brake system. When the air compressor compresses the air, it also compresses any moisture that may be present in the air. If this moisture is not removed, it can cause corrosion and damage to the brake components, leading to decreased braking performance and potentially dangerous situations on the road.

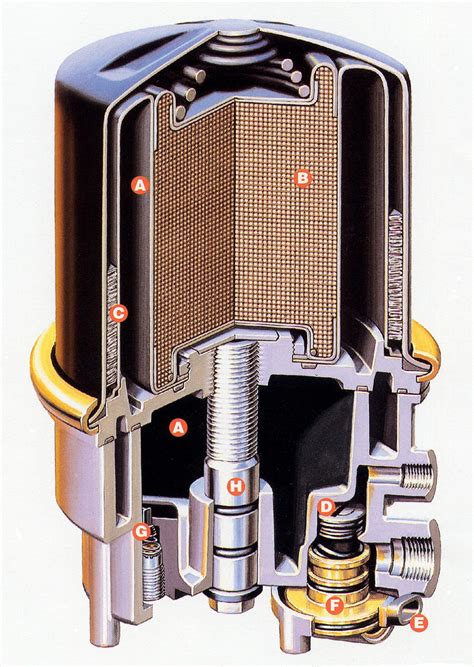

During the operation of a semi truck, the air dryer continuously filters and purifies the compressed air. It typically consists of three main components: the desiccant cartridge, purge valve, and check valve. The desiccant cartridge contains a material that absorbs moisture from the compressed air, while the purge valve releases the moisture and contaminants from the system. The check valve ensures that the filtered air flows in the correct direction.

How does a semi truck air dryer work?

When it comes to the functioning of a semi truck, there are numerous critical components that contribute to its efficient operation. One such component is the air dryer. A semi truck air dryer is a crucial part of the brake system that plays a significant role in ensuring the safety and performance of the vehicle.

The primary function of a semi truck air dryer is to remove moisture and contaminants from the compressed air system. The air system of a semi truck consists of an air compressor that generates compressed air used for various applications, such as operating the brakes. However, during the compression process, moisture and contaminants can enter the system, which can ultimately lead to the malfunctioning of various components.

To prevent these issues, the air dryer works by employing a two-stage process. In the first stage, the air enters the dryer, and a purge valve expels the accumulated debris before the air reaches the desiccant cartridge. The desiccant cartridge is the heart of the air dryer and is responsible for removing moisture from the compressed air. This cartridge contains a special desiccant material that acts as a sponge, effectively absorbing the moisture present in the air.

After the moisture is removed in the first stage, the compressed air then passes through the second stage, where it is filtered to remove any remaining contaminants. This stage usually includes a coalescing filter, which captures any remaining moisture droplets and particles. As a result, the air that exits the air dryer is clean, dry, and free from contaminants.

Regular maintenance and cleaning of the semi truck air dryer are essential for its proper functioning. This includes replacing the desiccant cartridge and filters at the recommended intervals to ensure optimal performance. Neglecting these maintenance tasks can lead to decreased efficiency, increased risk of brake failure, and higher operating costs.

In conclusion, the working principle of a semi truck air dryer involves a two-stage process of removing moisture and contaminants from the compressed air system. By ensuring regular maintenance and cleaning, truck owners can maximize the efficiency and reliability of their air dryer, leading to a safer and more efficient operation of their semi truck.

Importance of regular maintenance and cleaning

The regular maintenance and cleaning of a semi truck air dryer is of utmost importance to ensure its efficient functioning. An air dryer is a key component of a truck’s air brake system, and it plays a crucial role in removing moisture and contaminants from the compressed air. By maintaining and cleaning the air dryer on a regular basis, truck owners can prevent potential problems and ensure the smooth operation of their vehicle.

Regular maintenance and cleaning help in prolonging the lifespan of the air dryer. Over time, dirt, debris, and oil can accumulate in the dryer’s filter and valves, leading to clogs and reduced performance. Routine inspection and cleaning of these components can prevent such issues and maintain optimal functionality. Additionally, regular maintenance allows for the detection of any potential leaks or worn-out parts, which can be promptly addressed to prevent major breakdowns and expensive repairs.

Another important aspect of regular maintenance and cleaning is the prevention of moisture buildup. Moisture in the air brake system can cause corrosion, inhibit proper valve operation, and reduce the overall performance of the system. By regularly inspecting and cleaning the air dryer, moisture and condensation can be effectively removed, ensuring the longevity and reliability of the truck’s braking system.

Common problems and troubleshooting tips

Having a functioning and reliable air dryer is crucial for the proper operation of a semi truck. However, like any other mechanical component, air dryers can experience problems from time to time. In this blog post, we will discuss some of the common problems that you may encounter with your air dryer and provide you with troubleshooting tips to help resolve them.

1. Insufficient airflow: One of the most common problems with air dryers is insufficient airflow. This can result in moisture buildup in the air system, leading to potential damage to other components. To troubleshoot this issue, check for any clogs or restrictions in the air dryer filter or lines. Clean or replace the filter if necessary and ensure that all connections are secure.

2. Excessive noise: Excessive noise coming from the air dryer could indicate mechanical issues. Firstly, check for any loose or damaged parts. Tighten any loose connections and replace any worn-out components. If the noise persists, it may be a sign of a more serious problem, and it is advisable to consult a professional technician.

3. Water leakage: Water leakage is another common problem that can occur with air dryers. If you notice water dripping or leaking from your air dryer, it could be a sign of a faulty drain valve or diaphragm. Inspect these components for any damage or wear and replace them if needed. Additionally, make sure that the drain valve is functioning properly and not clogged with debris.

4. Failure to purge: The purge valve is responsible for removing moisture from the air system. If your air dryer fails to purge, it can result in moisture buildup and reduced efficiency. Start by checking the electrical connections to ensure they are secure. Moreover, inspect the purge valve for any blockages or damage and replace it if necessary.

5. Inconsistent drying: If your air dryer is not consistently drying the air, it may indicate a problem with the desiccant cartridge. Over time, the desiccant material can become saturated and lose its effectiveness. Consider replacing the desiccant cartridge according to the manufacturer’s recommended schedule. Additionally, check for any leaks that may be allowing moisture to enter the system.

By addressing these common problems promptly and following the troubleshooting tips provided, you can ensure that your semi truck air dryer operates efficiently and effectively. Remember, regular maintenance and inspection are key to preventing potential issues and maintaining optimal performance. If you encounter any major problems or are unsure about the troubleshooting process, it is always recommended to consult a professional technician.

Benefits of upgrading to a new air dryer

If you are a truck driver or fleet owner, you know how important it is to have a reliable and efficient semi truck air dryer. The air dryer plays a crucial role in maintaining the air quality and preventing moisture from entering the air brake system. Over time, however, air dryers can wear out and become less effective. In this blog post, we will discuss the benefits of upgrading to a new air dryer for your semi truck.

First and foremost, upgrading to a new air dryer can significantly improve the performance and reliability of your truck’s braking system. As air dryers age, they may not be able to remove moisture from the compressed air as efficiently, which can lead to brake problems such as reduced braking power and longer stopping distances. By investing in a new air dryer, you can ensure that your braking system operates at its optimal level, providing you with enhanced safety and peace of mind on the road.

Another benefit of upgrading to a new air dryer is improved fuel efficiency. An inefficient air dryer may cause the compressor to work harder to compensate for the moisture in the air system. This, in turn, can lead to increased fuel consumption. By replacing your old air dryer with a newer, more efficient model, you can minimize the strain on the compressor and potentially save on fuel costs in the long run.

Choosing the right air dryer for your semi truck

When it comes to maintaining your semi truck, the air dryer is an important component that shouldn’t be overlooked. The air dryer plays a crucial role in ensuring the safety, efficiency, and performance of your vehicle’s braking system. It helps to prevent moisture, contaminants, and oil from entering the air brake system, which can cause corrosion, clogs, and other issues. To ensure optimal performance of your semi truck, it is essential to choose the right air dryer that suits your specific needs and requirements.

One of the key factors to consider when selecting an air dryer for your semi truck is the type of air compressor you have. There are two main types of air compressors: the single-cylinder compressor and the twin-cylinder compressor. The single-cylinder compressor is more commonly found in smaller trucks, while the twin-cylinder compressor is often found in larger, heavy-duty trucks. Depending on your specific application and requirements, you need to choose an air dryer that is compatible with the type of air compressor in your semi truck.

Another important factor to consider is the capacity of the air dryer. The capacity of an air dryer refers to its ability to remove moisture and contaminants from the air brake system. It is usually measured in terms of standard cubic feet per minute (SCFM) and is directly related to the size and demands of your semi truck’s air brake system. It is crucial to choose an air dryer with a capacity that matches or exceeds the needs of your braking system to ensure proper moisture removal and optimal performance.

Expert tips for maximizing air dryer efficiency

When it comes to maintain the efficiency of a semi truck air dryer, there are several expert tips that can help you maximize its performance and make sure it operates smoothly. By following these tips, you can extend the lifespan of the air dryer and prevent any potential issues from occurring. Let’s take a look at some of the top recommendations for maximizing air dryer efficiency:

Regular Cleaning and Maintenance: One of the most important things you can do to keep your air dryer in optimal condition is to perform regular cleaning and maintenance. This includes cleaning the air dryer’s filter, checking for any blockages or debris, and ensuring that all connections are tight and secure. By keeping the air dryer clean, you can prevent any build-up that could interfere with its operation.

Check for Air Leaks: Another tip for maximizing air dryer efficiency is to regularly check for air leaks. Air leaks can occur in various parts of the system, including the air dryer itself, the air lines, and the fittings. By inspecting for and fixing any air leaks, you can prevent the air dryer from working overtime and minimize its energy consumption.

Monitor the Air Dryer’s Temperature: It’s important to keep an eye on the air dryer’s temperature to ensure it is within the recommended range. Most air dryers have a temperature sensor or gauge that allows you to monitor the temperature. If the temperature exceeds the recommended level, it could indicate an issue with the air dryer or the system, and it should be addressed promptly.

Frequently Asked Questions

What is a semi truck air dryer?

A semi truck air dryer is a component of the air braking system that removes moisture and contaminants from the compressed air before it enters the brake valves. It is essential for maintaining efficient brake performance and preventing damage to the braking system.

How does a semi truck air dryer work?

A semi truck air dryer works by using a combination of filtration and desiccant material to remove moisture and contaminants from the compressed air. The air passes through various filters and then through a desiccant cartridge, where moisture is absorbed. The dry air is then released into the brake system.

What is the importance of regular maintenance and cleaning of a semi truck air dryer?

Regular maintenance and cleaning of a semi truck air dryer is crucial to ensure its proper functioning. Over time, the desiccant material can become saturated and lose its effectiveness, leading to reduced air drying capacity. Additionally, accumulation of dirt and debris can restrict airflow, causing the air dryer to work less efficiently.

What are some common problems with semi truck air dryers and troubleshooting tips?

Common problems with semi truck air dryers include inadequate drying, air leaks, and desiccant material degradation. Troubleshooting tips include checking for air leaks, replacing worn-out desiccant cartridges, and cleaning or replacing filters. It is also advisable to consult the manufacturer’s manual for specific troubleshooting steps.

What are the benefits of upgrading to a new air dryer for a semi truck?

Upgrading to a new air dryer for a semi truck can provide several benefits. These include improved moisture removal, enhanced air drying capacity, increased reliability, and extended lifespan. Newer models may also have additional features such as electronic diagnostics for easier maintenance and better performance.

How can I choose the right air dryer for my semi truck?

To choose the right air dryer for your semi truck, consider factors such as the truck’s braking system specifications, air demand requirements, and compatibility with existing components. It is recommended to consult with a trusted supplier or manufacturer for expert guidance and to ensure proper fit and function.

What are some expert tips for maximizing air dryer efficiency in a semi truck?

To maximize air dryer efficiency in a semi truck, it is important to conduct regular inspections and maintenance, including checking for air leaks, cleaning or replacing filters, and monitoring desiccant cartridge saturation levels. Additionally, avoiding excessive moisture exposure and draining air tanks regularly can help maintain optimal air drying performance.