Everything You Need to Know About EGR Valve in Semi-Trucks: A Comprehensive Guide

What is an EGR valve?

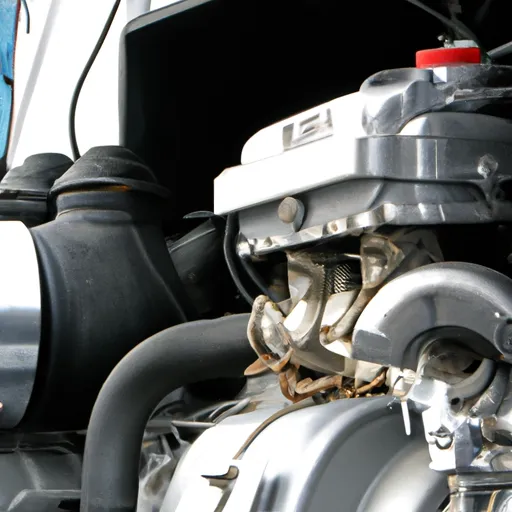

The EGR valve, or Exhaust Gas Recirculation valve, is an essential component in the engine of a semi-truck. Its primary function is to reduce the amount of harmful emissions that are released into the environment by recirculating a portion of the exhaust gases back into the combustion chamber. This process reduces the production of nitrogen oxides, which are known to cause smog and contribute to air pollution.

The EGR valve works by opening and closing a valve that allows exhaust gas to flow back into the engine’s combustion chamber. This process lowers the combustion temperature, reducing the amount of nitrogen oxides produced. The amount of gas that is recirculated is controlled by the engine’s computer, which uses various sensors to monitor the engine’s performance.

There are different types of EGR valves used in semi-trucks, including vacuum-operated, electrically-operated, and pneumatic-operated valves. Each type operates slightly differently, but they all serve the same purpose of reducing emissions.

Understanding the function and operation of the EGR valve is crucial for maintaining the engine’s performance and avoiding potential issues. In the next chapter, we will discuss the common signs of a faulty EGR valve that can help you identify potential problems early on.

Signs of a Faulty EGR Valve

While the EGR valve is a critical component in a semi-truck’s engine, it can sometimes malfunction and cause issues. It’s essential to recognize the common signs of a faulty EGR valve to address the problem before it leads to more significant engine damage. Here are some common symptoms to look out for:

1. Rough Idling

A faulty EGR valve can cause the engine to idle roughly or even stall. This occurs because the valve is not functioning correctly, and the engine may not be getting enough air or fuel.

2. Decreased Fuel Efficiency

If the EGR valve is stuck open, it can cause the engine to consume more fuel than usual. This is because the valve allows too much exhaust gas into the engine, which can result in decreased fuel efficiency.

3. Check Engine Light

A malfunctioning EGR valve can trigger the check engine light to come on. This is because the engine’s computer is detecting an issue with the valve or its performance.

4. Reduced Engine Power

A faulty EGR valve can cause the engine to lose power, resulting in reduced acceleration and slower overall performance.

If you notice any of these symptoms, it’s essential to have your semi-truck inspected by a qualified mechanic to diagnose the issue. In the next chapter, we will discuss how to properly maintain your EGR valve to prevent these issues from occurring.

Maintenance of EGR Valves

Proper maintenance of the EGR valve is crucial for ensuring the engine’s optimal performance and avoiding costly repairs. Here are some steps you can take to maintain your EGR valve:

1. Regular Cleaning

EGR valves can become clogged with carbon buildup over time, affecting their performance. Regular cleaning can prevent this issue from occurring. To clean the EGR valve, remove it from the engine and use a cleaning solution to remove any buildup.

2. Replacing Worn-out Parts

EGR valves have various components that can wear out over time, including the diaphragm and solenoid. Replacing worn-out parts can help maintain the valve’s optimal performance.

3. Using High-Quality Fuel and Oil

Using high-quality fuel and oil can prevent carbon buildup in the EGR valve, prolonging its lifespan.

4. Regular Inspection

Regular inspections of the EGR valve can help identify potential issues early on, preventing further engine damage.

It’s crucial to follow the manufacturer’s recommended maintenance schedule for your semi-truck to ensure that the EGR valve is properly maintained. Neglecting the valve’s maintenance can lead to expensive repairs and decreased engine performance. In the next chapter, we will discuss how to replace an EGR valve if it is beyond repair.

How to Replace an EGR Valve

If your EGR valve is beyond repair or has reached the end of its lifespan, it’s essential to replace it promptly to avoid further engine damage. Here are the steps to follow when replacing an EGR valve:

1. Locate the EGR Valve

The EGR valve is typically located on the engine’s intake manifold. Consult your semi-truck’s owner manual to locate the valve’s exact position.

2. Remove the Old EGR Valve

Disconnect the valve from the engine’s vacuum lines and electrical connections. Unscrew the valve from the intake manifold using a wrench.

3. Install the New EGR Valve

Install the new EGR valve in the same position as the old valve. Tighten the valve with a wrench, and reconnect the vacuum lines and electrical connections.

4. Test the New EGR Valve

Start the engine and test the new EGR valve’s performance. Check for any leaks or unusual noises.

Replacing an EGR valve can be a complicated process, and it’s recommended to have a qualified mechanic perform the replacement to ensure that it is done correctly. In the final chapter, we will discuss the importance of the EGR valve and its impact on the environment.

The Importance of EGR Valves for the Environment

EGR valves play a critical role in reducing harmful emissions from semi-truck engines, making them crucial for protecting the environment. Here are some ways that EGR valves help reduce emissions:

1. Reducing Nitrogen Oxide (NOx) Emissions

EGR valves reduce NOx emissions by recirculating a portion of the exhaust gas back into the engine. This process lowers the engine’s combustion temperature, reducing the formation of NOx.

2. Meeting Emissions Regulations

EGR valves are required by law in many countries to meet emissions regulations. Failure to comply with these regulations can result in hefty fines and damage to the environment.

3. Increasing Fuel Efficiency

EGR valves can also increase fuel efficiency by reducing the engine’s temperature and preventing unnecessary fuel consumption.

By reducing emissions and improving fuel efficiency, EGR valves play a critical role in protecting the environment and promoting sustainable transportation practices. It’s essential to properly maintain and replace EGR valves to ensure that they continue to function correctly and reduce emissions effectively.

In conclusion, understanding the EGR valve’s function and importance is crucial for maintaining a semi-truck’s engine’s optimal performance and protecting the environment. Regular maintenance, proper usage of high-quality fuel and oil, and timely replacement of worn-out parts and faulty EGR valves can help keep semi-trucks running smoothly and reduce their impact on the environment.

For detailed information, you can contact us at torqueusa.com.