Introduction to Air Spring and Traditional Suspension

In the world of truck suspension, there are various options available, each with its own set of advantages and disadvantages. Two popular choices are air spring suspension and traditional suspension. Understanding the differences between these two systems is crucial for truck owners and enthusiasts alike. In this blog post, we will delve into the mechanics of air spring suspension and traditional suspension, exploring their respective workings, as well as the pros and cons associated with each. By the end, you’ll have a better understanding of which suspension system might be the best fit for your truck.

Introduction to Air Spring and Traditional Suspension

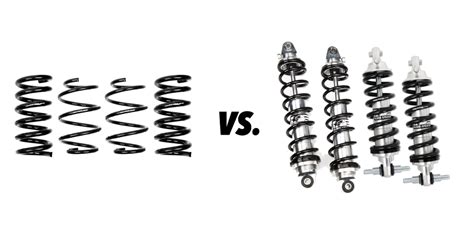

An air spring is a type of suspension component used in vehicles, particularly trucks, to provide a smooth and comfortable ride. It is designed to absorb shocks and vibrations from the road, ensuring a stable and controlled driving experience. In contrast, traditional suspension systems rely on mechanical components such as springs and shock absorbers to achieve similar goals.

The air spring is made up of a rubber bladder filled with pressurized air. This bladder is placed between the axle and the frame of the vehicle, providing support and cushioning. When the vehicle encounters bumps or uneven surfaces, the air spring compresses and expands, absorbing the impact and minimizing vibrations. This results in a smoother ride for both the driver and passengers.

One of the advantages of air spring suspension for trucks is its adjustable nature. By varying the air pressure in the bladder, the ride height and stiffness of the suspension can be customized to suit different loads and driving conditions. This flexibility allows trucks to maintain optimal performance and stability, whether they are carrying a heavy load or running empty.

However, there are also disadvantages to consider. Air springs can be more expensive to install and maintain compared to traditional suspension systems. They are also more complex, requiring additional components such as air compressors and air tanks. If a failure occurs, repairing or replacing these components can be costlier and time-consuming.

In contrast to air spring suspension, traditional suspension systems primarily rely on mechanical components. These include springs, which support the vehicle’s weight, and shock absorbers, which dampen and control any oscillations caused by road irregularities. Traditional suspensions are typically more straightforward and less expensive to install and maintain compared to air spring systems.

Despite their simplicity, traditional suspensions have their own set of advantages and disadvantages. One advantage is their durability, as they are less prone to leaks or air pressure issues. They are also generally more easily repairable, as the components are commonly available. However, traditional suspensions often offer a less comfortable ride compared to air spring systems, especially on rough or uneven terrains.

Ultimately, the choice between air spring and traditional suspension depends on the specific needs and preferences of the truck owner. Factors such as load capacity, terrain, and budget should be taken into consideration. Whether it’s the adjustable flexibility of air spring suspension or the simplicity and cost-effectiveness of traditional suspension, both have their own merits in providing a reliable and comfortable ride for trucks.

What is an Air Spring?

An air spring, also known as an airbag or air suspension, is a type of suspension system used in vehicles to provide a smooth and comfortable ride. Unlike traditional steel or coil springs, air springs use compressed air to support the weight of the vehicle and absorb the shocks and vibrations caused by uneven road surfaces. They are commonly found in heavy-duty trucks, buses, and luxury vehicles.

One of the key components of an air spring is the airbag itself. It is usually made of a reinforced rubber material and is designed to hold the compressed air. The airbag is connected to an air compressor, which pumps air into the bag to increase its stiffness and support the weight of the vehicle.

Air springs are adjustable, allowing the driver or the vehicle’s suspension control system to vary the amount of air pressure in the bags. This adjustability allows for a customizable and flexible ride, as the stiffness and height of the suspension can be altered to suit different road conditions or cargo loads.

How Does an Air Spring Suspension Work?

An air spring suspension is a type of suspension system used in vehicles, particularly in trucks. It is designed to provide a smooth and comfortable ride by utilizing air-filled rubber bags, known as air springs, instead of traditional coil or leaf springs. These air springs are connected to the vehicle’s axle and body, and they work by using compressed air to support the weight of the vehicle.

When the vehicle encounters uneven road surfaces or bumps, the air springs compress and expand to absorb the shocks and vibrations. This helps to isolate the vehicle’s body from the road, resulting in a smoother and more stable ride. The air springs are adjustable, allowing the driver to customize the level of support and comfort required based on the road conditions and load weight.

One of the key components of an air spring suspension system is the air compressor. This compressor is responsible for supplying the compressed air to the air springs, ensuring that they remain inflated and provide the necessary support. The compressor is usually controlled by an onboard computer system, which monitors the vehicle’s weight distribution and adjusts the air pressure accordingly.

Additionally, an air spring suspension system often includes an air reservoir, which acts as a storage tank for the compressed air. This reservoir helps to maintain a consistent air pressure, even during sudden changes in load or road conditions. It also enables the air springs to respond quickly to any adjustments in air pressure, ensuring a smooth and controlled ride.

- Improved Ride Quality: The use of air springs in the suspension system provides a smoother and more comfortable ride compared to traditional suspensions. The air springs absorb shocks and vibrations more effectively, resulting in reduced driver and passenger fatigue.

- Adjustable Support: Air springs offer the advantage of adjustable support. The air pressure can be increased or decreased to suit the desired level of firmness or softness, providing a customizable riding experience.

- Enhanced Load-Carrying Capacity: Air spring suspensions have a higher load-carrying capacity compared to traditional suspensions. The adjustable air pressure allows for better weight distribution and increased stability, making it ideal for trucks that need to haul heavy loads.

| Advantages | Disadvantages |

|---|---|

| Improved ride quality | Higher cost compared to traditional suspensions |

| Adjustable support | Requires regular maintenance and servicing |

| Enhanced load-carrying capacity | Complex design and installation process |

In conclusion, an air spring suspension works by utilizing air-filled rubber bags to provide support and cushioning to a vehicle. It offers several advantages such as improved ride quality, adjustable support, and enhanced load-carrying capacity. However, it also has some disadvantages, including higher cost, regular maintenance requirements, and a more complex design and installation process. Overall, air spring suspensions are a viable option for trucks that prioritize comfort, stability, and versatility in their suspension systems.

Advantages of Air Spring Suspension for Trucks

When it comes to vehicle suspension systems, air spring suspension for trucks has become increasingly popular in recent years. This innovative technology offers several advantages over traditional suspension systems, making it a preferred choice for many truck owners. In this blog post, we will explore some of the key advantages of air spring suspension for trucks.

1. Improved Ride Quality: One of the major advantages of air spring suspension for trucks is the enhanced ride quality it offers. Air springs offer a smoother and more comfortable ride as compared to traditional leaf spring suspensions. The air springs can adjust their stiffness and damping characteristics based on the road conditions and load, providing a more stable and comfortable ride for both the driver and the passengers.

2. Adjustable Load Capacity: Another significant advantage of air spring suspension is its ability to adjust the load capacity of the truck. Air springs can be inflated or deflated to accommodate different loads, allowing the truck to maintain optimal ride height and balance regardless of the weight being carried. This flexibility is particularly beneficial for commercial trucks that often transport varying loads.

3. Enhanced Vehicle Stability: Air spring suspension systems contribute to improved stability and handling of trucks. The adjustable stiffness of the air springs allows for better control and responsiveness, especially during cornering and sudden maneuvers. This increased stability not only enhances the overall driving experience but also improves safety on the road.

4. Reduced Wear and Tear: Air springs help reduce wear and tear on other components of the truck’s suspension system. By absorbing shocks and vibrations more efficiently, air springs can minimize the strain on other parts, such as shocks, tires, and axles. This ultimately leads to less frequent maintenance and repair costs, making air spring suspension a cost-effective choice for truck owners.

5. Leveling Capability: Air spring suspension systems offer the added benefit of leveling capability. Trucks equipped with air springs can adjust the ride height, compensating for uneven or sloping surfaces. This feature is especially advantageous when loading or unloading cargo, ensuring that the truck remains level and stable, even with varying load weights.

| Advantages of Air Spring Suspension for Trucks |

|---|

| Improved Ride Quality |

| Adjustable Load Capacity |

| Enhanced Vehicle Stability |

| Reduced Wear and Tear |

| Leveling Capability |

In conclusion, the advantages of air spring suspension for trucks are numerous and make it an attractive choice for truck owners seeking superior ride quality, adjustable load capacity, enhanced stability, reduced wear and tear on components, and leveling capability. With these benefits, it is no wonder that air spring suspension systems are increasingly being adopted in the trucking industry.

Disadvantages of Air Spring Suspension for Trucks

The air spring suspension system offers several advantages for trucks, such as improved ride comfort, increased load-carrying capacity, and adjustable ride height. However, like any technology, it also has its drawbacks. In this blog post, we will explore the disadvantages of air spring suspension for trucks.

One of the main disadvantages of air spring suspension is the potential for air leaks. As the air springs are filled with pressurized air, any leakage can result in reduced suspension performance. Even a small leak can cause a noticeable decrease in ride quality and handling. To ensure optimal performance, regular inspections and maintenance of the air springs are necessary.

Another downside of air spring suspension is the cost. Compared to traditional suspension systems, air spring suspension can be more expensive to install and maintain. The system requires additional components, such as air compressors, air tanks, and control modules, which add to the overall cost. Moreover, repairing or replacing damaged air springs can be costly, especially if the vehicle is out of warranty.

| Disadvantages of Air Spring Suspension |

|---|

| 1. Potential for air leaks |

| 2. Higher cost compared to traditional suspension |

| 3. Limited availability of repair facilities |

Additionally, another disadvantage of air spring suspension for trucks is the limited availability of repair facilities. As air spring suspension systems are relatively newer technology, not all repair shops may have the necessary expertise and equipment to service or repair these systems. This can lead to longer waiting times and increased service costs if specialized repair facilities need to be sought out.

In conclusion, while air spring suspension offers numerous benefits for trucks, such as improved ride comfort and load-carrying capacity, it also has its disadvantages. These include the potential for air leaks, higher installation and maintenance costs, and limited availability of repair facilities. Before considering air spring suspension for your truck, it is essential to weigh these drawbacks against the advantages to make an informed decision.

What is a Traditional Suspension for Trucks?

A traditional suspension for trucks refers to the system that supports the vehicle’s weight and provides a comfortable ride by absorbing shocks and vibrations. It consists of several components, including springs, shock absorbers, and control arms.

The main purpose of a traditional suspension is to maintain tire contact with the road surface and control the up and down movement of the wheels. This helps improve stability, handling, and overall ride quality. The most common type of traditional suspension is the coil spring suspension, which uses steel coil springs to support the vehicle’s weight.

In addition to coil springs, traditional suspensions may also use leaf springs, which are long, flat strips of metal stacked on top of each other. Leaf spring suspensions are often found in heavy-duty trucks and provide excellent load-carrying capabilities.

How Does a Traditional Suspension Work?

A traditional suspension system is a mechanical system used in vehicles to absorb shocks and vibrations from the road surface. It is composed of several components, including springs, shock absorbers, and control arms, that work together to provide a smooth and comfortable ride. In this article, we will explore how a traditional suspension system works and its key components.

The main component of a traditional suspension system is the spring. The spring is responsible for supporting the weight of the vehicle and absorbing the impact from bumps and uneven surfaces. It helps to maintain the ride height and controls the vertical movement of the vehicle. The most commonly used type of spring in traditional suspensions is the coil spring, which is made of a series of tightly wound metal coils.

In addition to the spring, a traditional suspension system also includes shock absorbers. Shock absorbers play a crucial role in controlling the oscillations of the spring and damping the vibrations caused by road disturbances. They work by converting the kinetic energy of the suspension movement into heat energy, which is then dissipated into the surrounding air. This helps to reduce the bouncing and bouncing of the vehicle, ensuring a smoother and more stable ride.

Advantages of Traditional Suspension for Trucks

The traditional suspension system is a fundamental component of trucks, playing a crucial role in providing stability and control on the road. While air spring suspension systems have gained popularity in recent years, traditional suspensions still offer a range of advantages for trucks. In this blog post, we will explore the advantages of traditional suspension systems and why they continue to be a preferred choice in the trucking industry.

1. Reliability: One of the significant advantages of traditional suspension systems is their proven reliability. Designed with simplicity in mind, these suspensions consist of a series of mechanical components such as springs, shock absorbers, and control arms. Unlike air springs, which can be susceptible to leaks and punctures, traditional suspensions are less prone to failures, ensuring consistent performance over time.

2. Durability: Traditional suspensions are known for their robustness and ability to withstand heavy loads. Built with sturdy materials, such as steel and aluminum, these suspensions can handle the demanding conditions faced by trucks on a daily basis. This durability not only ensures a longer lifespan but also reduces maintenance and repair costs, making traditional suspensions an economical choice for truck owners.

3. Cost-effectiveness: Another advantage of traditional suspensions is their affordability. Compared to air spring suspensions, which require complex electronic systems and additional components, traditional suspensions are more cost-effective both in terms of installation and maintenance. This makes them an attractive option for truck owners who prioritize value for money without compromising on performance.

| Advantages of Traditional Suspension for Trucks |

|---|

| Reliability |

| Durability |

| Cost-effectiveness |

In conclusion, while air spring suspensions have their merits, traditional suspension systems offer a range of advantages that continue to make them a preferred choice for trucks. Their proven reliability, durability, and cost-effectiveness contribute to their widespread use in the trucking industry. Whether it’s handling heavy loads or enduring challenging road conditions, traditional suspensions have stood the test of time, providing a stable and dependable ride for truck drivers.

Disadvantages of Traditional Suspension for Trucks

When it comes to truck suspensions, there are two main types: air spring suspension and traditional suspension. In this blog post, we will specifically focus on the disadvantages of traditional suspension for trucks.

Traditional suspension, also known as leaf spring suspension, has been used for many years in the trucking industry. It consists of multiple layers of curved metal strips, called leaf springs, which are mounted to the axles and frame of the truck. While this type of suspension has its advantages, it also comes with several drawbacks.

One of the major disadvantages of traditional suspension is its limited ability to provide a smooth and comfortable ride. Leaf springs are known to be quite stiff, which means they do not absorb shocks and vibrations as effectively as air springs. This can result in a bumpy and jarring ride, especially when driving on rough terrain or uneven roads.

- Inadequate load handling: Another drawback of traditional suspension is its limited load-handling capability. Leaf springs have a fixed load capacity, which means they may not be able to handle heavy loads as efficiently as air springs. This can lead to decreased stability and control of the truck, posing a potential safety risk.

- Uneven weight distribution: Traditional suspension systems often have an uneven weight distribution. The weight of the truck and its cargo may not be evenly distributed across all the leaf springs, causing uneven wear and tear on the suspension components. This can lead to premature failure of the suspension system and increased maintenance costs.

- Limited adjustability: Unlike air spring suspensions, traditional suspensions do not offer much adjustability. Once the leaf springs are installed, their characteristics, such as stiffness and ride height, cannot be easily adjusted or fine-tuned. This lack of adjustability can make it difficult to optimize the truck’s performance and ride quality for different driving conditions.

In conclusion, while traditional suspension has been a long-standing choice for trucks, it does come with its fair share of disadvantages. Limited ride comfort, inadequate load handling, uneven weight distribution, and limited adjustability are all factors that can affect the overall performance and safety of trucks equipped with traditional suspension systems. As advancements in suspension technology continue to evolve, it may be worth considering the advantages of air spring suspension as a potential alternative.