Air brakes are a crucial part of any commercial vehicle’s braking system, providing efficient and reliable stopping power. Understanding the components that make up an air brake system is essential for optimal performance and safety. In this blog post, we will provide an overview of the various air brake components, explain their importance, and discuss their function and working. Additionally, we will explore the role of the air compressor and air dryer, examine brake chambers and valves, and offer maintenance and troubleshooting tips for these vital components. Get ready to dive into the world of air brakes and enhance your knowledge for a safer ride.

Overview of Air Brake Components

An air brake system is a vital component of any vehicle that relies on compressed air to stop or slow down. While most people are familiar with the concept of air brakes, they may not fully understand the various components that make up this important system. In this blog post, we will provide an overview of the key air brake components and their functions.

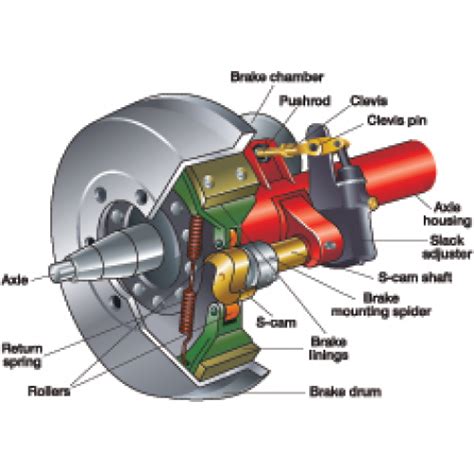

First and foremost, let’s discuss the **brake chamber**. This is a crucial component that converts compressed air into mechanical force to apply the brakes. The brake chamber consists of a diaphragm, a push rod, and a return spring. When compressed air enters the chamber, it pushes against the diaphragm, causing the push rod to extend and activate the brakes. When the air pressure is released, the return spring pulls the push rod back, releasing the brakes.

Another essential component of an air brake system is the **air compressor**. As the name suggests, the air compressor is responsible for generating compressed air. It draws in clean air from the surroundings and pressurizes it, which is then stored in air tanks to be used when needed. The air compressor is typically powered by the engine of the vehicle, ensuring a continuous supply of compressed air for the brake system.

Next, let’s talk about the air dryer. The air dryer plays a crucial role in removing moisture from the compressed air before it enters the brake system. Moisture can cause corrosion and damage to the various components of the system. By removing moisture, the air dryer helps to ensure the longevity and efficiency of the air brake system. It does this by using a desiccant material or a refrigeration process to remove moisture from the air.

In addition to these key components, there are various other air brake components, such as valves, hoses, and reservoirs. These components work together to control the flow of compressed air and engage the brakes when needed. For instance, air brake valves regulate the pressure and distribution of compressed air, allowing the driver to control the braking force.

Overall, an understanding of the various air brake components is essential for maintaining and troubleshooting the brake system of any vehicle. By being familiar with these components and their functions, drivers and mechanics can ensure the safe and efficient operation of their vehicles. If you want to learn more about specific air brake components or dive deeper into their maintenance and troubleshooting, stay tuned for our upcoming blog posts on these topics!

Understanding Air Brake System

The air brake system is a crucial component in any heavy-duty vehicle, ensuring safety and control on the road. Understanding how it works and its various components is essential for drivers and maintenance personnel alike. In this blog post, we will provide an in-depth overview of the air brake system, examining the function and working of its key components, and highlighting the significance of regular maintenance and troubleshooting.

Air Brake Components:

The air brake system is composed of several components that work together to ensure effective braking. These components include:

- Air Compressor

- Air Dryer

- Brake Chambers

- Air Brake Valves

Air Compressor:

The air compressor is the heart of the air brake system, providing compressed air to operate the brakes. It draws in air from the atmosphere and compresses it to a high pressure, storing it in the air reservoirs.

Air Dryer:

The air dryer plays a critical role in maintaining the quality of the compressed air. It removes moisture and contaminants from the air before it enters the brake system, preventing corrosion and damage to the components.

Brake Chambers:

Brake chambers convert the compressed air into mechanical force to actuate the brakes. They are responsible for applying the necessary pressure to the brake shoes or pads, resulting in vehicle deceleration or stopping.

Air Brake Valves:

Air brake valves control the flow of pressurized air throughout the system, enabling the driver to apply or release the brakes. They play a crucial role in modulating brake pressure for smooth and controlled braking.

Maintenance and Troubleshooting:

Regular maintenance of air brake components is essential to ensure their proper functioning and prevent potential failures. This includes regular inspections, cleaning, lubrication, and replacement of worn-out parts. Effective troubleshooting techniques should also be employed to identify and rectify any issues that may arise.

In conclusion, understanding the air brake system and its components is vital for the safe operation of heavy-duty vehicles. By comprehending the function and working of key components such as the air compressor, air dryer, brake chambers, and air brake valves, drivers and maintenance personnel can ensure the system operates smoothly and efficiently. Regular maintenance and troubleshooting practices further enhance the overall performance and reliability of the air brake system.

Importance of Air Brake Components

When it comes to ensuring the safety of a vehicle, air brake components play a crucial role. These components are essential for the proper functioning of the air brake system, which is widely used in heavy-duty vehicles such as trucks and buses. The importance of air brake components cannot be overstated, as they directly impact the braking performance and overall safety of the vehicle.

One of the key reasons why air brake components are so important is their ability to handle heavy loads. Heavy-duty vehicles often carry substantial weight, and traditional hydraulic brake systems may not be sufficient to handle this load effectively. Air brake components, on the other hand, can provide the necessary force to bring such vehicles to a stop, even under heavy load conditions.

Another significant advantage of air brake components is their reliability. Unlike hydraulic systems that can be susceptible to fluid leaks and other issues, air brake systems are more robust and less prone to failure. This reliability is of utmost importance, especially in commercial vehicles that are regularly exposed to demanding operating conditions.

- Increased stopping power: Air brake components provide the necessary force to bring heavy-duty vehicles to a stop, even under heavy load conditions.

- Reliability: Air brake systems are less prone to failure compared to hydraulic systems, ensuring the safety and efficiency of the braking system.

- Efficient heat dissipation: Air brake components, such as brake chambers and valves, are designed to handle the heat generated during braking, preventing overheating and associated issues.

- Enhanced control: Air brake components allow for precise control of the braking force, leading to improved handling and maneuverability of the vehicle.

In conclusion, the importance of air brake components in ensuring vehicle safety and performance cannot be underestimated. From providing the necessary stopping power to ensuring reliability and control, these components play a vital role in heavy-duty vehicles’ braking systems. Proper maintenance and regular inspections of air brake components are essential to ensure their optimum functionality, reducing the risks associated with brake failure and improving overall road safety.

| Type of Air Brake Components | Function |

|---|---|

| Air Compressor | Supplies compressed air to the air storage tanks. |

| Air Dryer | Removes moisture and contaminants from the compressed air. |

| Brake Chambers | Converts compressed air into the mechanical force to actuate the brakes. |

| Air Brake Valves | Controls the flow and pressure of the compressed air. |

Types of Air Brake Components

In an air brake system, there are several components that work together to ensure the safe operation of a vehicle. Each component plays a crucial role in helping the system function effectively and efficiently. In this blog post, we will explore the different types of air brake components and their functions.

1. Air Compressor: The air compressor is the heart of an air brake system. It is responsible for compressing air and supplying it to other components. The compressor draws in air from the surroundings and compresses it to a high pressure. This pressurized air is then stored in the air reservoirs for future use.

2. Air Reservoirs: The air reservoirs, also known as air tanks, store the compressed air generated by the air compressor. They act as a storage facility, ensuring that a sufficient amount of pressurized air is available when needed. The size and number of air reservoirs may vary depending on the size and type of the vehicle.

3. Brake Chambers: Brake chambers are responsible for converting the air pressure into mechanical force to activate the brakes. There are two main types of brake chambers – spring brake chambers and service brake chambers. Spring brake chambers are used for parking and emergency brakes, while service brake chambers are used for applying the brakes during normal operation.

4. Brake Valves: Brake valves are essential components that control the flow and release of air in the air brake system. There are several types of brake valves, including relay valves, quick release valves, and proportioning valves. Each valve has a specific function and helps in regulating the braking process.

5. Air Dryer: The air dryer is responsible for removing moisture and contaminants from the compressed air. It prevents moisture from entering the brake system, which could lead to corrosion and reduced braking performance. The air dryer plays a vital role in maintaining the overall effectiveness of the air brake system.

6. Brake Calipers and Discs: In vehicles equipped with disc brakes, brake calipers and discs are important components of the air brake system. The brake calipers house the brake pads and apply pressure to the discs to generate friction, allowing the vehicle to slow down or come to a stop. These components work in conjunction with the air brake system to ensure effective braking.

| Component | Function |

|---|---|

| Air Compressor | Compresses air and supplies it to other components |

| Air Reservoirs | Store compressed air for future use |

| Brake Chambers | Convert air pressure into mechanical force to activate brakes |

| Brake Valves | Control the flow and release of air in the system |

| Air Dryer | Remove moisture and contaminants from the compressed air |

| Brake Calipers and Discs | Generate friction to slow down or stop the vehicle |

These are just a few examples of the many components that make up an air brake system. Each component has its own specific function, and their proper operation is crucial for the overall safety and performance of the vehicle. Understanding the different types of air brake components can help drivers and mechanics identify issues and perform necessary maintenance and troubleshooting.

Function and Working of Air Compressor

An air compressor is a crucial component of an air brake system that plays a significant role in the functioning of various air brake components. Its primary function is to convert power, typically from an electric motor or a combustion engine, into potential energy stored in compressed air. This compressed air is then used to perform various tasks and functions within the air brake system.

One of the key functions of the air compressor is to supply compressed air to the air storage tanks of the air brake system. These tanks store the compressed air and act as reservoirs, providing a steady and reliable supply of compressed air to the brakes when needed. The compressor continuously operates to maintain the air pressure within the storage tanks at an optimal level, ensuring that the air brake system functions efficiently.

Additionally, an air compressor is responsible for pressurizing the air used in other components of the air brake system. For instance, it provides the necessary air pressure to operate the brake chambers, which are crucial for applying and releasing the brakes. The compressed air generated by the compressor also powers various air brake valves, allowing for the effective control and modulation of the braking force.

- Air Storage Tanks: Receive and store the compressed air from the air compressor.

- Brake Chambers: Utilize the compressed air to apply and release the brakes.

- Air Brake Valves: Control and regulate the flow of compressed air within the air brake system.

| Component | Function |

|---|---|

| Air Intake Filter | Filters incoming air, removing dust and contaminants. |

| Compressor Pump | Pressurizes the air and increases its potential energy. |

| Pressure Switch | Monitors and controls the air pressure within the compressor. |

| Motor | Provides the power to drive the compressor pump. |

| Tank | Stores the compressed air for future use. |

| Pressure Relief Valve | Prevents the tank from over-pressurizing. |

Understanding the function and working of an air compressor is essential for anyone involved in the maintenance and troubleshooting of air brake components. Regular inspection, maintenance, and proper functioning of the compressor ensure the overall effectiveness and safety of the air brake system. By providing the necessary compressed air to various components, the air compressor plays a critical role in the smooth operation of air brakes and ensures reliable braking performance in various vehicles.

Role of Air Dryer in the Air Brake System

The air dryer plays a crucial role in the air brake system, ensuring the proper functioning of the brakes and overall safety of the vehicle. It is an essential component that helps to remove moisture and contaminants from the compressed air before it reaches the brake system. By doing so, it prevents the potential damage that can occur due to moisture, such as corrosion, freezing, and reduced efficiency of the brakes.

One of the critical functions of the air dryer is to remove moisture from the compressed air. When the air compressor compresses air, it also traps water vapor. This moisture can cause significant issues in the brake system, such as corrosion and freezing. The air dryer uses various mechanisms, such as desiccants or refrigeration, to cool and condense the air, separating the moisture and contaminants. This ensures that only clean and dry air is directed into the brake system, preventing any potential damage.

In addition to moisture removal, the air dryer also filters out contaminants, such as oil, dust, and debris. These contaminants can enter the system through the air compressor or external sources. If not removed, they can lead to clogging and malfunctioning of various air brake components. The air dryer typically includes filters that effectively remove these contaminants, ensuring the air reaching the brake system remains clean and free from any harmful particles.

- Moisture removal: Air dryer removes moisture from the compressed air, preventing corrosion and freezing in the brake system.

- Contaminant filtration: It filters out contaminants like oil, dust, and debris, preventing clogging and malfunctioning of brake components.

- Protection of brake system: By removing moisture and contaminants, the air dryer helps to protect the brake system and ensures its efficient operation.

| Advantages of Air Dryer |

|---|

| Prevents corrosion and freezing in the brake system |

| Increases the lifespan of brake components |

| Ensures consistent and reliable braking performance |

| Reduces maintenance and repair costs |

| Improves overall safety of the vehicle |

In conclusion, the air dryer plays a vital role in the air brake system by removing moisture and contaminants from the compressed air. Its functions of moisture removal and contaminant filtration ensure the brake system’s efficient operation, prevent corrosion and freezing, and increase the lifespan of brake components. By investing in a high-quality air dryer and regular maintenance, vehicle owners can enhance the safety, reliability, and performance of their air brake system.

Significance of Brake Chambers

Brake chambers play a crucial role in the functioning of an air brake system. They are one of the key components responsible for converting air pressure into mechanical force, which in turn initiates the braking action in a vehicle. Brake chambers are designed to generate the required amount of force to engage the brakes effectively, ensuring the safety of passengers and cargo. They are widely used in heavy-duty vehicles such as trucks, buses, and trailers, making their significance undeniable in the world of transportation.

One of the primary reasons why brake chambers are highly significant is their capability to convert air pressure into mechanical force efficiently. As air pressure builds up within the brake chamber, it pushes against a diaphragm, causing it to expand and push the push rod. The push rod then transfers this force to the foundation brakes, leading to their activation. This mechanical force generated by the brake chamber is crucial in bringing the vehicle to a stop or maintaining its speed while descending downhill.

Another important aspect of brake chambers is their ability to withstand extreme conditions and ensure reliable braking performance. These components are designed to be durable and resistant to environmental factors, such as moisture, heat, and vibrations. Brake chambers are often exposed to harsh road conditions and undergo heavy usage. Hence, their construction and materials used are specifically chosen to ensure longevity and consistent performance, minimizing the need for frequent replacements and repairs.

- Durability: Brake chambers are built to withstand harsh road conditions and heavy usage, ensuring long-lasting performance.

- Force Conversion: The ability to convert air pressure into mechanical force is crucial in engaging the braking system effectively.

- Reliable Performance: Brake chambers ensure consistent and reliable braking performance, contributing to the overall safety of the vehicle and its occupants.

| Advantages | Disadvantages |

|---|---|

| Efficient conversion of air pressure into mechanical force. | May require periodic maintenance and inspections to ensure proper functioning. |

| Enhanced safety by providing reliable braking performance. | Brake chambers can be costly to replace if they fail or get damaged. |

| Designed to withstand harsh road conditions and heavy usage. | Improper installation or maintenance may lead to reduced brake efficiency. |

Examining Air Brake Valves

The proper functioning of air brake valves is crucial for the overall performance and safety of the air brake system. Air brake valves play a vital role in controlling the flow of compressed air, converting it into mechanical force to execute braking actions. Understanding the different types of air brake valves and their functions is essential for maintenance and troubleshooting purposes. In this blog post, we will examine air brake valves in detail, exploring their significance and components.

There are various types of air brake valves used in different components of the air brake system. Some of the commonly used valves include relay valves, quick release valves, check valves, and foot valves. Each valve has a specific function and is strategically placed within the system to ensure smooth and efficient brake operation.

One of the most critical components of an air brake valve is the diaphragm, which acts as a barrier between the air pressure chambers. When the brake pedal is depressed, the diaphragm allows compressed air to flow, activating the braking mechanism. It is crucial to regularly inspect and maintain the diaphragm to prevent any leaks or defects that could compromise brake performance.

- Examination of the diaphragm: Regularly inspect the diaphragm for signs of wear, cracks, or tears. Ensure that it is properly seated and not obstructed by any debris or foreign objects.

- Checking for leaks: Conduct a thorough inspection to identify any air leaks in the valve. Use a soap and water solution to test for leaks, as they create bubbles when air escapes.

- Testing valve responsiveness: Check the valve’s responsiveness by applying air pressure and observing how quickly it activates the braking system. Any delays or inconsistencies may indicate a faulty valve that requires immediate attention.

In addition to the diaphragm, air brake valves also consist of various other components such as springs, seals, and control ports. It is essential to inspect and maintain these components regularly to ensure optimal performance and minimize the risk of brake failure. Lubrication of moving parts is also crucial to prevent excessive wear and ensure smooth operation.

| Component | Function |

|---|---|

| Diaphragm | Controls the flow of compressed air to activate the braking mechanism |

| Springs | Provide the necessary force to return the valve to its resting position after braking action |

| Seals | Create airtight connections to prevent air leaks |

| Control ports | Regulate the flow and direction of compressed air within the valve |

In conclusion, air brake valves are critical components of the air brake system, responsible for controlling the flow of compressed air and ensuring efficient braking performance. Regular examination and maintenance of these valves are essential to identify and rectify any issues that may compromise the system’s safety and effectiveness. By paying attention to the various components and conducting routine inspections, you can ensure a reliable and secure air brake system.

Maintenance and Troubleshooting of Air Brake Components

Introduction:

Maintenance and troubleshooting of air brake components play a crucial role in ensuring the safety and efficiency of vehicles equipped with air brake systems. Regular maintenance and timely troubleshooting can help identify and resolve issues before they lead to brake failure or other problems. This article will provide an overview of common maintenance practices and troubleshooting techniques for various air brake components.

List of Common Air Brake Components:

Before delving into the maintenance and troubleshooting procedures, it is important to have a basic understanding of the key air brake components. These components include:

- Air compressor

- Air dryer

- Brake chambers

- Air brake valves

Maintenance Tips for Air Brake Components:

Proper maintenance of air brake components is essential for preventing unexpected failures and ensuring the longevity of the system. Here are some important maintenance tips:

- Regular inspection: Conduct routine inspections to check for any signs of wear, damage, or leakage in the air brake components. Pay special attention to hoses, valves, and fittings.

- Cleanliness: Keep all air brake components clean and free from dirt, debris, and oil. Contaminants can affect the performance of the system and lead to component failure.

- Lubrication: Follow the manufacturer’s recommendations for lubricating specific air brake components. Proper lubrication helps reduce friction and enhances the overall efficiency of the system.

- Torque checks: Periodically check the torque of fasteners, such as bolts and nuts, to ensure they are tightened to the correct specifications. Loose fasteners can lead to air leaks or component failures.

Troubleshooting Air Brake Components:

Despite proper maintenance, air brake components may still develop issues that require troubleshooting. Here are some common troubleshooting techniques:

| Issue | Possible Cause | Troubleshooting Technique |

|---|---|---|

| Air compressor not building enough pressure | Worn piston rings or cylinder, air leaks | Inspect for leaks, check compressor components, repair or replace as necessary |

| Brake chambers not applying or releasing properly | Corroded or damaged pushrods, faulty diaphragms | Inspect and clean pushrods, replace faulty diaphragms |

| Air brake valves not operating correctly | Contaminants in valve, worn seals or gaskets | Clean or replace air brake valves as needed |

Conclusion:

Maintenance and troubleshooting are vital aspects of ensuring the reliability and safety of air brake components. By following proper maintenance practices and utilizing effective troubleshooting techniques, potential issues can be identified and resolved promptly, reducing the risk of brake system failures. Regular inspections, cleanliness, lubrication, and torque checks are essential for maintaining the optimal performance of air brake components. In case of any problems, properly diagnosing and addressing them using appropriate troubleshooting techniques can help restore the functionality of the air brake system.