Air bags have become an essential safety feature in vehicles, significantly reducing the risk of injury during accidents. However, have you ever wondered how these life-saving devices actually work? In this blog post, we will explore the various components of an air bag system and delve into the mechanism behind its deployment. We will also discuss the importance of air bag inflation, the triggering process, and the role of speed and impact sensors. Additionally, we will explore the gas generation involved in air bag inflation, the deployment time and inflation force, as well as the post-inflation safety measures. Join us as we unravel the fascinating journey of air bag inflation and uncover the technology that protects millions of lives on the road.

The Importance of Air Bag Inflation

The importance of air bag inflation cannot be overstated when it comes to vehicle safety. Air bags are a crucial component of modern automotive systems and play a vital role in protecting occupants during accidents. They are designed to deploy rapidly and provide a cushioning effect, reducing the risk of serious injuries and fatalities. Without proper inflation, air bags would fail to provide the necessary protection, rendering them ineffective in preventing injuries in the event of a collision.

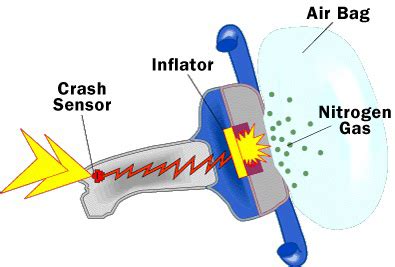

Firstly, let’s understand the components of an air bag system. An air bag system consists of several key components that work together to ensure proper deployment. These components include the air bag module itself, crash sensors, the diagnostic unit, and the inflator. The module is typically located in the steering wheel for the driver-side air bag and in various locations throughout the vehicle for side curtain airbags. Crash sensors detect the impact and send signals to the diagnostic unit, which then triggers the inflator to rapidly fill the air bag with gas. This entire process happens in a matter of milliseconds, illustrating the critical importance of the system’s efficiency and effectiveness.

Triggering the air bag inflation is a complex process that requires precise detection of a collision. The crash sensors used in modern air bag systems are designed to measure various parameters such as speed, force, and deceleration. These sensors can detect the severity of an impact and determine whether the air bags need to be deployed. Once a collision is detected, the diagnostic unit processes the information and sends a signal to the inflator, which then activates the gas generation process to rapidly inflate the air bags. This rapid deployment is crucial in providing a protective cushion for occupants and minimizing the risk of injury.

Components of an Air Bag System

In today’s blog post, we will be discussing the components of an air bag system. A vehicle’s air bag system is a crucial safety feature that helps protect drivers and passengers in the event of a collision. Although air bags may seem like a simple device, they are made up of several intricate components that work together to provide effective protection.

The main component of an air bag system is the air bag module itself. This module consists of an air bag cushion and an inflator. The air bag cushion is made of a strong, lightweight fabric that is designed to rapidly inflate upon impact. The inflator is responsible for producing the gas needed to inflate the air bag cushion. It contains a chemical propellant that ignites when a collision occurs, releasing a controlled amount of gas to inflate the air bag cushion.

Another important component of the air bag system is the crash sensors. These sensors are strategically placed throughout the vehicle and are designed to detect sudden deceleration or changes in vehicle dynamics that indicate a collision. Upon detecting a collision, the crash sensors send a signal to the air bag control module, which triggers the inflation process. This rapid deployment of the air bag system helps to protect the occupants from injury by cushioning their impact with the interior of the vehicle.

The air bag control module is another critical component of the air bag system. This module acts as the brain of the system, constantly monitoring the vehicle’s sensors for any signs of a collision. In the event of a collision, the control module uses complex algorithms to determine the severity and type of impact. Based on this information, it determines whether the air bag system should be activated and, if so, which air bags should be deployed.

Overall, the components of an air bag system work together in a highly coordinated manner to provide effective protection in the event of a collision. From the air bag module to the crash sensors and the control module, each component plays a vital role in ensuring the safety of the vehicle’s occupants. It is important for drivers to be aware of these components and their functionality, as it helps to instill confidence in the effectiveness of air bags as a safety feature.

Triggering the Air Bag Inflation

The triggering of air bag inflation is a critical aspect of automobile safety. When an accident occurs, the air bag system must be able to deploy rapidly and effectively to protect the occupants of the vehicle. In this blog post, we will delve into the various factors that contribute to triggering the air bag inflation process.

One of the key components involved in triggering the air bag inflation is the crash sensors. These sensors are strategically placed throughout the vehicle and are designed to detect sudden changes in acceleration or deceleration. When a significant impact is detected, the crash sensors send a signal to the air bag control module, which initiates the inflation process.

In addition to the crash sensors, another important component in triggering the air bag inflation is the air bag control module itself. This module serves as the brain of the system, constantly monitoring the information received from the crash sensors. Once the module receives the signal indicating a crash, it rapidly assesses the severity and determines whether or not air bag deployment is necessary.

Furthermore, the air bag control module takes into account various parameters such as the speed of the vehicle, the angle of impact, and the number of occupants in the vehicle. This data helps the module in deciding the appropriate level of deployment, ensuring that the air bags are inflated with the right amount of force to provide effective protection without causing unnecessary harm to the occupants.

Mechanism Behind Air Bag Deployment

The mechanism behind air bag deployment is a crucial aspect of vehicle safety that is often overlooked. When an accident occurs, the air bag system is designed to deploy rapidly and protect the occupants of the vehicle from serious injury. Understanding how this mechanism works can help us appreciate the importance of air bags and the technology behind their deployment.

At the heart of the air bag deployment mechanism are sensors that detect the severity of an impact. These sensors, which are usually located in the front of the vehicle, continuously monitor various factors such as acceleration, deceleration, and the rate of change of velocity. When a significant impact is detected, the sensors send a signal to the air bag control module, which then triggers the deployment process.

Once the signal is received, an electrical current is sent to the inflator module. This module contains a solid propellant that quickly burns and generates a large volume of gas. The gas generated by the inflator rapidly fills the air bag, causing it to expand and deploy within milliseconds. The force exerted by the gas expansion helps to cushion the occupants and reduce the risk of injury during a collision.

It is important to note that air bag deployment is a carefully timed process. The deployment time is carefully calibrated to occur within the first few milliseconds of a collision. This allows the air bag to be fully inflated and provide maximum protection to the occupants before they make contact with the inflating bag. The deployment force is also carefully controlled to prevent excessive force that could cause additional injuries.

- Sensors: Sensors play a crucial role in detecting the severity of an impact and triggering the deployment process.

- Inflator Module: The inflator module contains a solid propellant that generates gas to rapidly inflate the air bag.

- Deployment Timing and Force: The deployment of the air bag is carefully timed and controlled to provide maximum protection to the vehicle occupants.

| Component | Function |

|---|---|

| Sensors | Detect the severity of an impact |

| Air Bag Control Module | Triggers the deployment process |

| Inflator Module | Generates gas to rapidly inflate the air bag |

The mechanism behind air bag deployment showcases the advanced technology and engineering that goes into ensuring the safety of vehicle occupants during accidents. By understanding this mechanism, we can appreciate the lifesaving potential of air bags and the importance of proper maintenance and inspection to ensure their effectiveness. Remember, air bags are just one component of a comprehensive vehicle safety system, and they work in conjunction with other safety features such as seat belts and crumple zones to provide optimal protection in the event of a collision.

Speed and Impact Sensors in Air Bag Inflation

The use of airbags in vehicles has become a crucial safety measure that has greatly reduced the risk of injuries and fatalities in car accidents. One important aspect of airbag deployment is the role of speed and impact sensors. These sensors play a vital role in determining when and how an airbag should be inflated. Let’s take a closer look at the significance of speed and impact sensors in airbag inflation.

The speed sensor is a pivotal component of the airbag system. It measures the velocity at which the vehicle is traveling and sends this information to the airbag control unit. The impact sensor, on the other hand, detects any sudden deceleration or change in motion. Together, these sensors work in tandem to ensure that the airbag is deployed precisely at the right moment.

The main function of the speed sensor is to calculate the vehicle’s speed and determine if it exceeds a certain threshold. If the speed sensor detects that the vehicle is traveling below this threshold, it will prevent the airbag from deploying, as the impact may not be severe enough to warrant inflation. However, if the vehicle is traveling at a high speed and the impact sensor also detects a sudden change in motion, the airbag control unit will trigger the inflation process.

- Speed sensor: Measures the velocity of the vehicle.

- Impact sensor: Detects sudden deceleration or change in motion.

- Airbag control unit: Receives data from speed and impact sensors.

The data from the speed and impact sensors is relayed to the airbag control unit, which in turn activates the airbag inflator. The inflator is responsible for producing the gas necessary to fill the airbag rapidly. The gas generation process occurs within milliseconds to ensure that the airbag is fully inflated before the occupant makes contact with it. Once the airbag is inflated, it serves as a cushioning device, reducing the impact force exerted on the occupant during a collision.

In conclusion, speed and impact sensors are crucial components in the airbag inflation process. They work together to analyze the vehicle’s speed and motion, determining when it is necessary to trigger the airbag deployment. The integration of these sensors ensures that the airbags are only inflated during high-speed collisions, providing maximum protection to the vehicle occupants. With advancements in sensor technology, airbag systems have become even more reliable and effective in minimizing injuries in car accidents.

Gas Generation in Air Bag Inflation

The gas generation in air bag inflation plays a crucial role in determining the effectiveness of the safety system during a car accident. When a collision occurs, the air bag system needs to inflate rapidly to provide sufficient cushioning and protection to the occupants. The gas generation process involves the controlled release of a gas, which fills up the air bag and allows it to deploy quickly. There are different methods used for gas generation in air bag inflation, each with its own advantages and considerations.

One of the commonly used methods for gas generation in air bag inflation is the chemical reaction between sodium azide (NaN3) and potassium nitrate (KNO3). These two compounds are packed together in an inflator module, which is a canister located inside the air bag system. When a collision occurs, an electrical current is passed through a heating element, which ignites the sodium azide and causes it to decompose rapidly. This decomposition produces nitrogen gas (N2) and other harmless byproducts, which rapidly fill up the air bag and enable it to deploy in a matter of milliseconds.

Another method for gas generation in air bag inflation is the use of stored gas systems. In this approach, the air bag module contains a high-pressure gas canister, typically filled with nitrogen (N2) gas. When a collision is detected, a valve opens to release the pressurized gas into the air bag, causing it to inflate. This method provides a rapid and reliable inflation process, as there is no need for a chemical reaction to generate the gas. However, it requires regular maintenance to ensure the canister remains sufficiently pressurized.

In certain advanced air bag systems, a hybrid approach of both chemical reaction and stored gas systems is used for gas generation in air bag inflation. This combination allows for a more versatile and adaptable deployment process, as it can be optimized for different collision scenarios. For example, in a frontal collision, the chemical reaction gas generator may be primarily used, while in a side collision, the stored gas system can provide a faster response. This hybrid approach enables manufacturers to tailor the air bag deployment to specific crash conditions and enhance occupant protection.

- The gas generation process in air bag inflation is essential for rapid deployment and effective occupant protection.

- There are different methods used for gas generation, including chemical reactions, stored gas systems, and hybrid approaches.

- Chemical reactions involve the controlled decomposition of compounds such as sodium azide to produce nitrogen gas.

- Stored gas systems utilize pressurized nitrogen gas canisters to rapidly inflate the air bag.

- The hybrid approach combines both chemical reactions and stored gas systems for adaptability in different collision scenarios.

| Gas Generation Method | Advantages | Considerations |

|---|---|---|

| Chemical Reactions | – Rapid gas generation- Reliable inflation process | – Requires regular maintenance- Byproducts need to be harmless |

| Stored Gas Systems | – Rapid and reliable inflation- No need for chemical reaction | – Canister requires regular maintenance- Requires initial gas filling |

| Hybrid Approach | – Versatile and adaptable inflation- Tailored deployment for different collisions | – More complex system design- Additional considerations for integration |

Deployment Time and Inflation Force

The deployment time and inflation force are crucial factors in the functioning of an air bag system. The effectiveness of an air bag in protecting occupants during a collision depends on how quickly it deploys and how forcefully it inflates. These factors play a significant role in minimizing the impact of a crash on occupants and reducing the risk of severe injuries.

When a collision occurs, the air bag system activates within milliseconds to provide protection to the occupants. The deployment time refers to the speed at which the air bag is fully inflated and positioned to shield the occupants from an impact. The faster the air bag deploys, the lesser the time occupants have to come into contact with the vehicle’s interior or other objects, thereby reducing the risk of injuries.

The inflation force of an air bag determines the level of protection it can provide. It refers to the pressure exerted by the inflating air bag to prevent the occupants from hitting hard surfaces during a collision. The inflation force is carefully calibrated to ensure that it is sufficient enough to absorb the impact of the collision and protect the occupants, but not excessive to cause harm or injuries by itself.

Both the deployment time and inflation force are influenced by various components and mechanisms within the air bag system. These include the crash sensors, the inflator, and the air bag itself. The crash sensors detect the severity of the impact and send a signal to the inflator to release the necessary amount of gas for inflation. The inflator, which contains a propellant or a gas generator, rapidly produces gas or initiates a chemical reaction to inflate the air bag. The air bag then rapidly fills with gas, expanding and deploying to provide protection for the occupants.

In summary, the deployment time and inflation force of an air bag are critical factors in ensuring occupant safety during a collision. Swift deployment and adequate inflation force help to reduce the risk of injuries by minimizing the time occupants have to encounter the vehicle’s interior or external objects. These factors are carefully calibrated through the use of sensors, inflators, and other components within the air bag system to provide effective protection without causing harm to the occupants themselves.

Inflation Process for Side Air Bags

Side air bags are an important safety feature in modern vehicles, providing additional protection to passengers during side-impact collisions. The inflation process of side air bags plays a crucial role in ensuring their effectiveness. In this blog post, we will explore the mechanism behind the inflation process for side air bags and understand how it works to safeguard passengers in the event of a side collision.

The inflation process for side air bags begins with a triggering event, typically an impact or collision detected by the vehicle’s sensors. These sensors, which are strategically placed within the vehicle, monitor various parameters such as the force and direction of impact. Once the sensors detect a side collision, they send signals to the central control unit of the air bag system, initiating the inflation process.

The inflation process involves the release of gas from an inflator module. This module contains a gas generator that produces the required gas for inflation. When triggered, the gas generator rapidly combusts a solid propellant, producing a large amount of gas. The gas is then directed through a filter and into the air bag, inflating it within milliseconds.

The speed and impact sensors in the air bag system play a vital role in ensuring the timely and appropriate inflation of side air bags. These sensors provide crucial data regarding the severity of the collision, allowing the air bag system to adjust the inflation force accordingly. The inflation force is determined by the speed and impact of the collision, ensuring optimal protection for the passengers.

- Fast inflation: The inflation process for side air bags occurs almost instantaneously, ensuring rapid deployment and protection for the occupants.

- Optimized inflation force: The speed and impact sensors enable the air bag system to adjust the inflation force based on the severity of the collision, minimizing the risk of injury.

- Expanded coverage: Side air bags are designed to provide protection to the head, chest, and torso regions of the occupants, reducing the risk of injuries during side-impact collisions.

| Benefits of Side Air Bags |

|---|

| 1. Enhanced safety during side-impact collisions |

| 2. Reduces the risk of head, chest, and torso injuries |

| 3. Provides additional protection to occupants |

The inflation process for side air bags is a critical component of the overall air bag system. It ensures rapid deployment, appropriate inflation force, and expanded coverage to minimize injuries during side-impact collisions. These safety features play a significant role in enhancing occupant safety and reducing the severity of injuries in real-world accidents. As technology continues to advance, we can expect further improvements in side air bag systems, enhancing passenger safety in the event of a side collision.

Post-Inflation Safety Measures

After the initial deployment of an airbag, there are several important safety measures that need to be taken to ensure the well-being of the occupants in a vehicle. These post-inflation safety measures are crucial in minimizing the risk of injury and maximizing the effectiveness of the airbag system.

One of the first safety measures involves staying seated and properly restrained after the airbag has deployed. It is important for occupants to remain in their seats and keep the seat belts fastened. This helps to prevent any secondary impacts and reduces the risk of being ejected from the vehicle in the event of a subsequent collision.

Another important post-inflation safety measure is to check for any injuries or medical conditions that may have resulted from the airbag deployment. While airbags are designed to protect occupants, they can still cause injuries such as abrasions, burns, or even broken bones. It is crucial to assess any injuries and seek medical attention if necessary.

Furthermore, it is recommended to have the vehicle inspected by a professional after the airbag deployment. This can help identify any damage or malfunctions that may have occurred during the inflation process. It is essential to ensure that the airbag system is properly functioning and ready to provide protection in case of another accident.

- Stay seated and properly restrained.

- Check for any injuries or medical conditions.

- Have the vehicle inspected by a professional.

| Post-Inflation Safety Measures: |

|---|

| 1. Stay seated and properly restrained. |

| 2. Check for any injuries or medical conditions. |

| 3. Have the vehicle inspected by a professional. |